🚀 Why Choose Conductive PP Trays for Electronics?

In the precision electronics industry, maximizing vertical storage space while ensuring immediate accessibility is critical. Our ESD Trays and Flat Boxes are engineered to solve this specific challenge. Unlike deep turnover crates, these low-profile conductive containers are designed for flat components such as Printed Circuit Boards (PCBs), LCD panels, and optical lenses.

Manufactured from carbon-infused Conductive Polypropylene (PP), our trays provide a permanent Faraday cage effect. This ensures that your sensitive components are shielded from electrostatic discharge (ESD) during assembly, transport, and inspection processes.

💎 Key Technical Features & Benefits

To rank for technical queries, we highlight the specific engineering advantages of our product line:

1. Permanent ESD Protection

- Surface Resistance: 104−106Ω (Conductive).

- Material: The anti-static property is intrinsic to the composite material, meaning it will never wash off, migrate, or degrade over time, unlike topical coatings.

2. Space-Saving Low Profile

- Design: With heights starting at just 20mm, these trays allow for high-density stacking of flat parts.

- Benefit: Ideal for SMT lines and drying racks where vertical clearance is limited but volume is high.

3. Workflow Efficiency

- Visibility: Shallow walls ensure 100% visibility of contents.

- Accessibility: Operators can retrieve small parts or boards without digging deep into a bin, reducing handling time and physical stress on components.

📋 Catalog: ESD Tray Models & Dimensions

Search engines prioritize structured data. This table is optimized for "Featured Snippets."

Series A: Standard ESD Trays (PCB & Component)

Best for: Circuit boards, tablets, and sub-assemblies.

| Model Name | Ext. Dimensions (L×W×H mm) | Int. Dimensions (L×W×H mm) | Profile Type |

|---|---|---|---|

| 1# A Tray | 370 × 245 × 64 | 345 × 220 × 57 | Standard |

| 2# A Tray | 432 × 280 × 75 | 407 × 265 × 70 | Standard |

| 3# A Tray | 560 × 366 × 70 | 530 × 335 × 65 | Large Format |

| 4# Tray | 315 × 230 × 43 | 307 × 223 × 35 | Compact |

| 5# Tray | 620 × 415 × 95 | 570 × 375 × 85 | High Capacity |

| 6# Tray | 453 × 295 × 67 | 435 × 280 × 47 | Medium |

| 9# Tray | 345 × 225 × 50 | 315 × 200 × 45 | Compact |

| 10# Tray | 375 × 295 × 20 | 345 × 270 × 15 | Ultra-Shallow |

| 12# Tray | 438 × 285 × 50 | 395 × 264 × 43 | Medium |

| 13# Tray | 415 × 305 × 34 | 397 × 297 × 25 | Shallow |

| 16# Tray | 340 × 240 × 30 | 325 × 225 × 20 | Small Parts |

Series B: Reinforced & Heavy-Duty Trays

Best for: Heavier loads and rigorous industrial use.

| Model Name | Ext. Dimensions (L×W×H mm) | Int. Dimensions (L×W×H mm) | Feature |

|---|---|---|---|

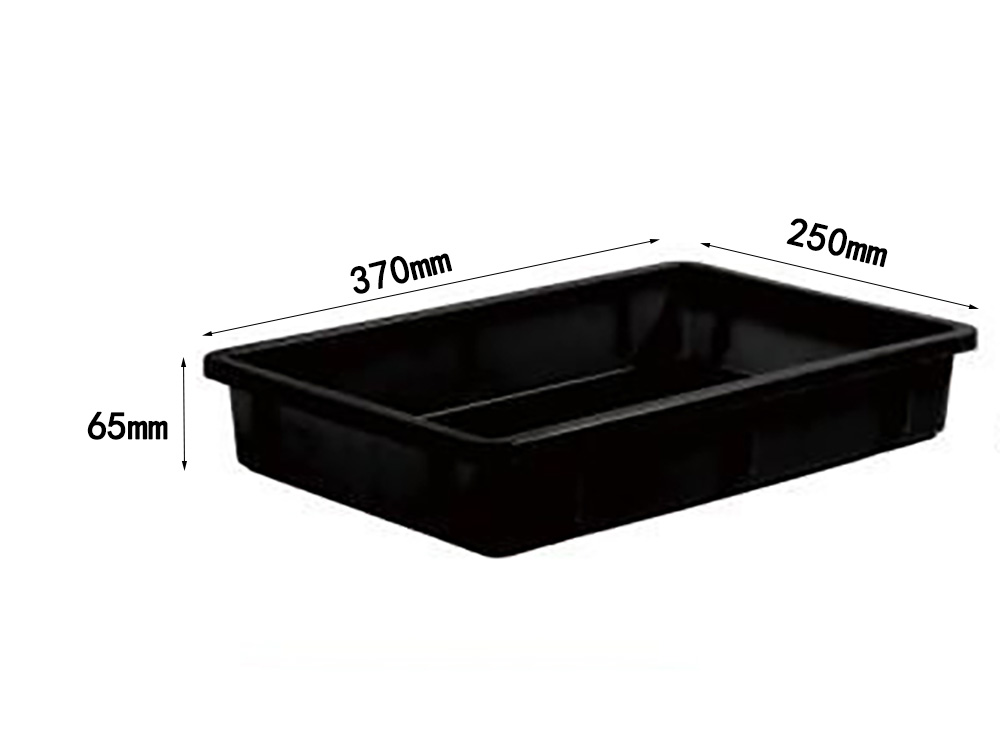

| Double A1# Tray | 370 × 250 × 65 | 345 × 220 × 55 | Reinforced Ribs |

| Double A2# Tray | 435 × 280 × 80 | 405 × 280 × 74 | Reinforced Ribs |

| Thickened 8# | 438 × 295 × 85 | 407 × 265 × 75 | Extra Wall Thickness |

Series C: Flat Boxes & Utility Trays

Best for: Hardware sorting, tools, and small loose parts.

| Model Name | Ext. Dimensions (L×W×H mm) | Int. Dimensions (L×W×H mm) | Description |

|---|---|---|---|

| 01 Flat Box | 152 × 96 × 55 | 132 × 82 × 47 | Smallest Flat Box |

| 02 Flat Box | 205 × 135 × 60 | 180 × 115 × 55 | Small Utility |

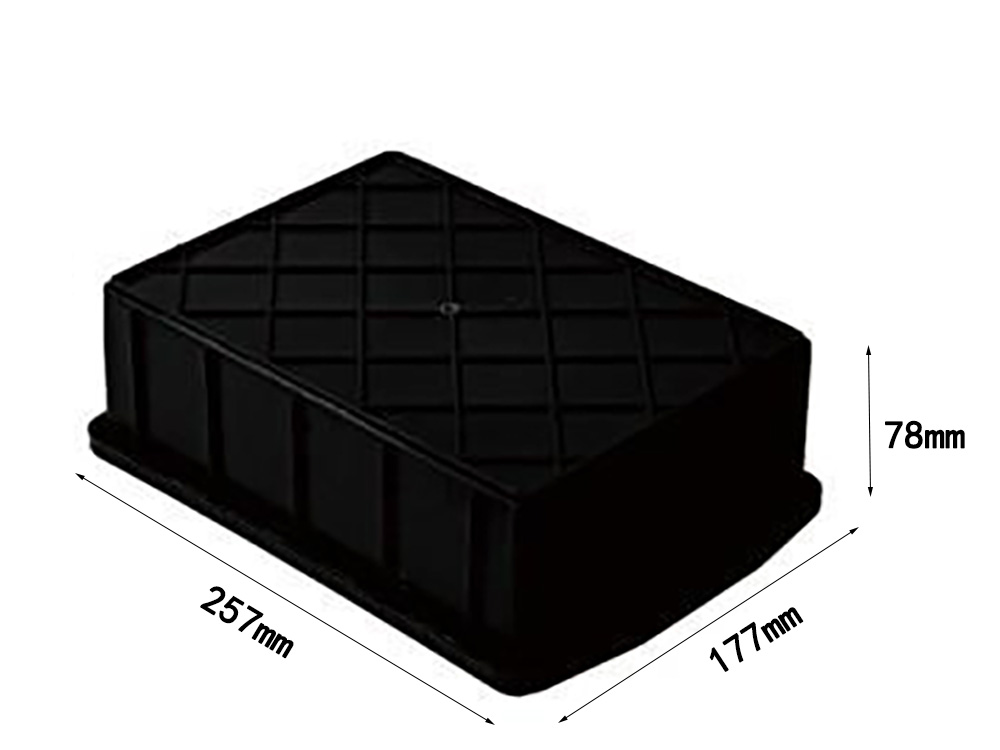

| 03 Flat Box | 257 × 177 × 78 | 223 × 156 × 70 | Medium Utility |

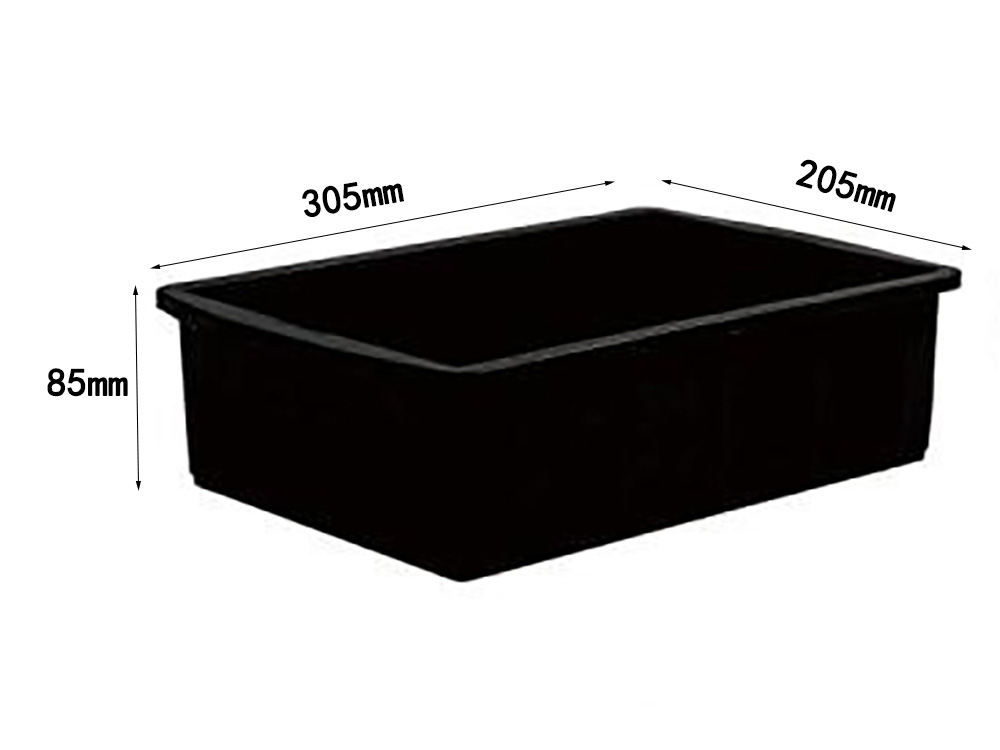

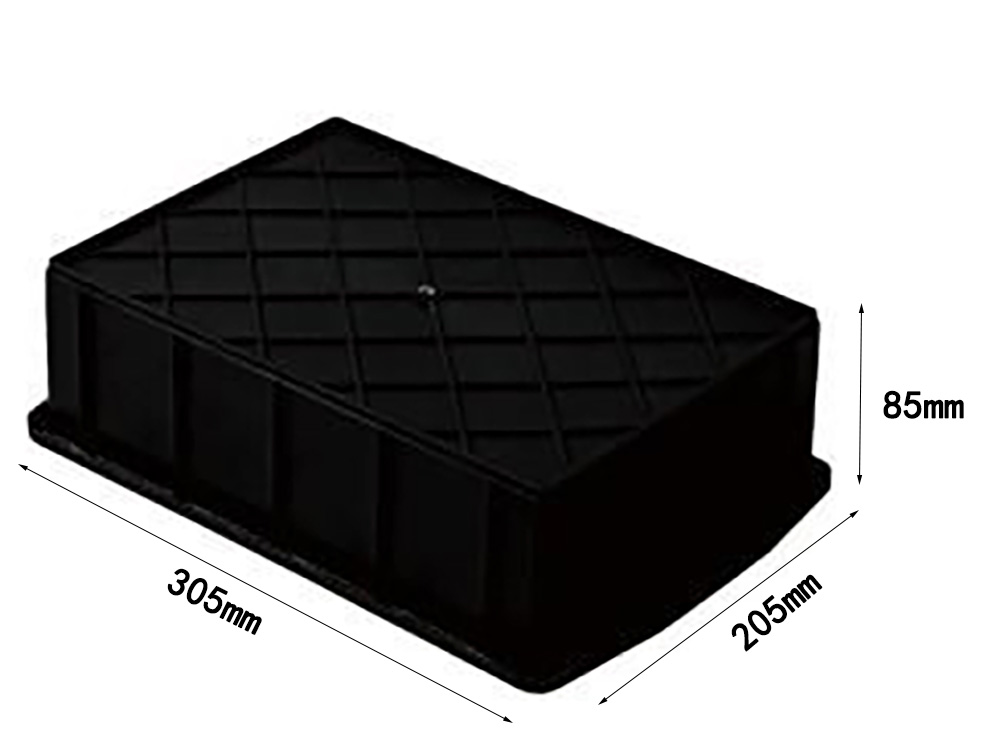

| 04 Flat Box | 305 × 205 × 85 | 270 × 185 × 77 | Large Utility |

| 7# Tea Tray | 340 × 250 × 30 | 295 × 215 × 25 | Sorting Tray |

| 8# Tea Tray | 345 × 255 × 40 | 300 × 215 × 35 | Sorting Tray |

🏭 Industrial Applications

Our ESD trays are trusted across various high-tech sectors. By listing these, we help Google match your page to specific industry searches.

- PCB Assembly & Manufacturing: Safe transport of "Work-In-Progress" (WIP) boards between soldering and testing stations.

- Cleanroom Environments: The low-dust, easy-to-clean PP material is suitable for ISO-rated cleanrooms.

- Mobile & Tablet Repair: Organizing disassembled screens, logic boards, and screws in a static-safe manner.

- Optical & Lens Storage: The shallow depth prevents stacking damage to delicate glass components.

❓ Frequently Asked Questions (FAQ)

Optimized for Google's "People Also Ask" section.

What is the difference between an ESD Tray and an ESD Box?

ESD Trays are typically shallower (height < 100mm) and designed for flat items like PCBs or single-layer component storage. ESD Boxes (or totes) are deeper and used for bulkier items or large quantities of loose parts.

Do these conductive trays require lids?

Most of our ESD trays are designed to be self-stacking. The bottom of the top tray acts as a lid for the tray below it, preventing dust entry. However, they are generally open-top containers for quick access.

Is the anti-static protection permanent?

Yes. We use carbon-loaded polypropylene, meaning the conductive material is mixed throughout the plastic. It is not a surface coating, so the ESD protection lasts for the entire lifespan of the product, even after washing.

Can I wash these trays with industrial solvents?

Yes, our conductive PP trays are chemically resistant to most standard industrial cleaning agents, alcohol, and water, making them easy to maintain in a clean production environment.