Our ESD plastic pallets (Electrostatic Discharge) are specifically engineered for the high-tech industry. Featuring a specialized conductive or dissipative additive, these pallets provide a permanent path to ground, protecting sensitive electronic components from static damage during storage and transit.

The 9-leg (nestable) design offers a perfect balance of structural integrity and space efficiency. Whether you are managing an SMT production line or a cleanroom warehouse, these pallets ensure your high-value assets remain "static-safe."

📊 Technical Specifications

Product Parameters

Below is the structured data for our standard 9-leg anti-static series. These models are designed to meet international ESD standards.

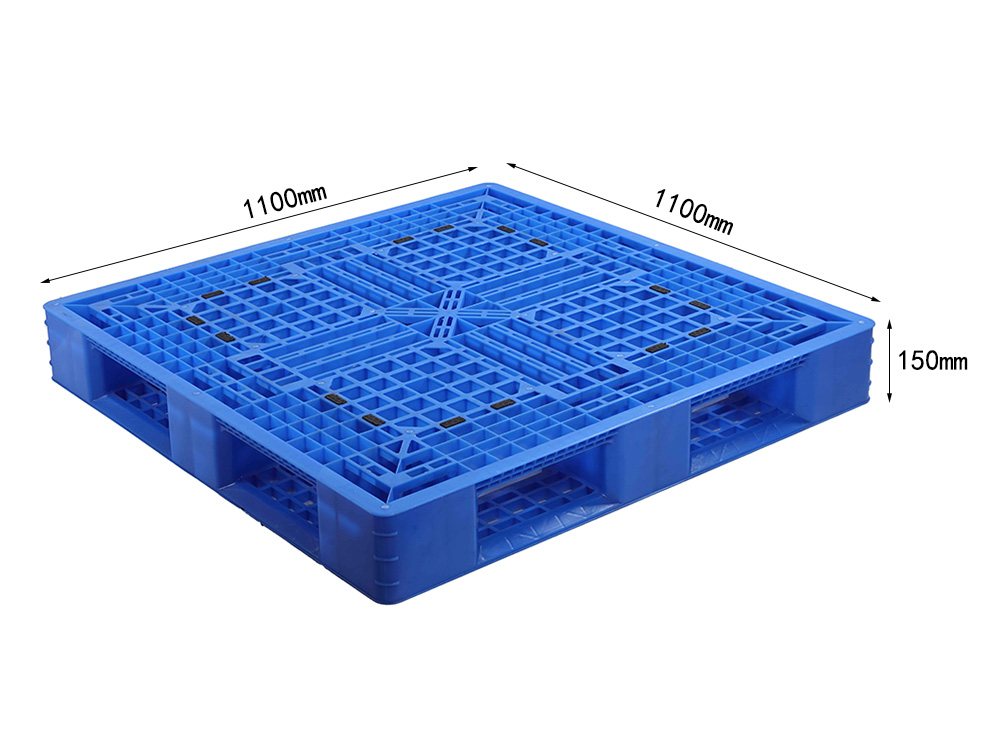

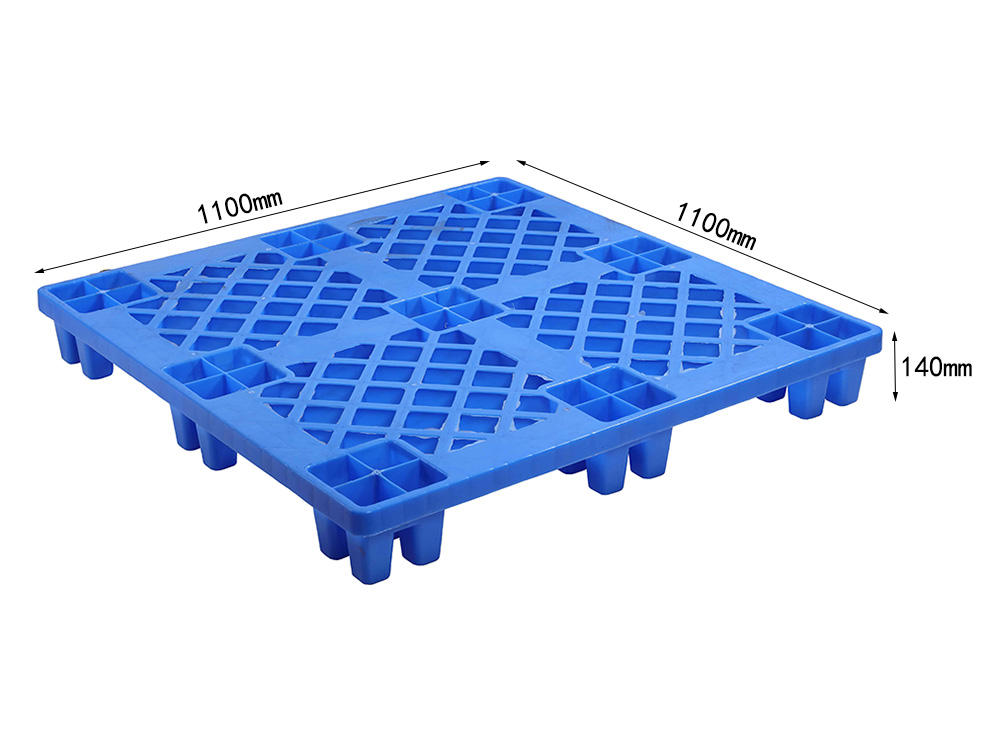

| Model No. | Dimensions (L×W×H mm) | Dynamic Load | Static Load | Design Type |

|---|---|---|---|---|

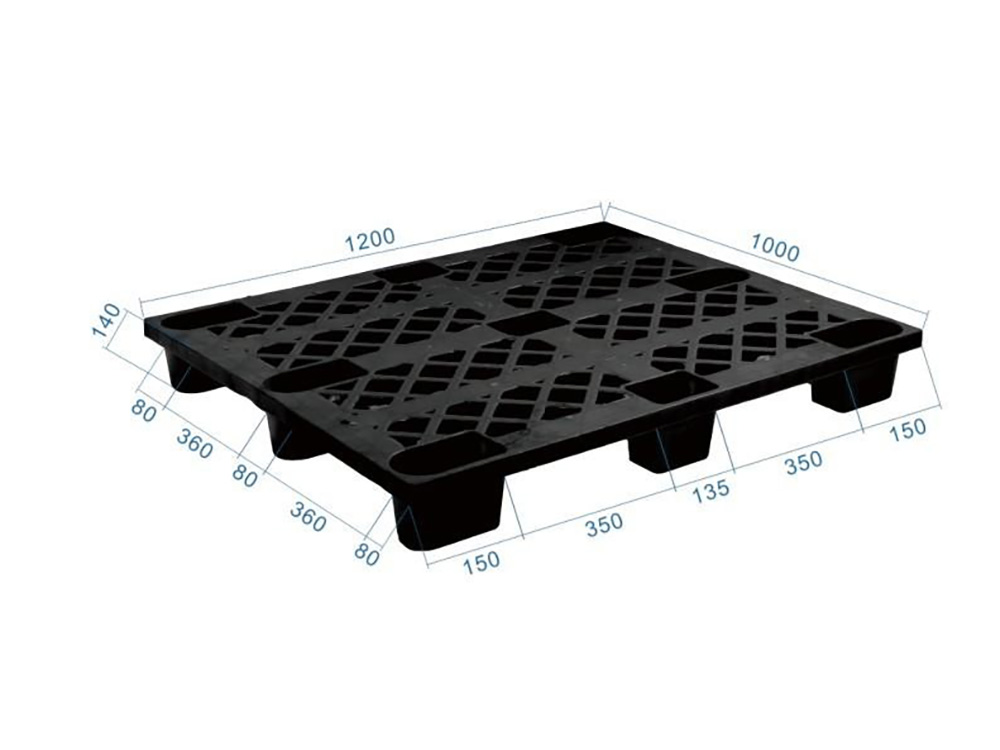

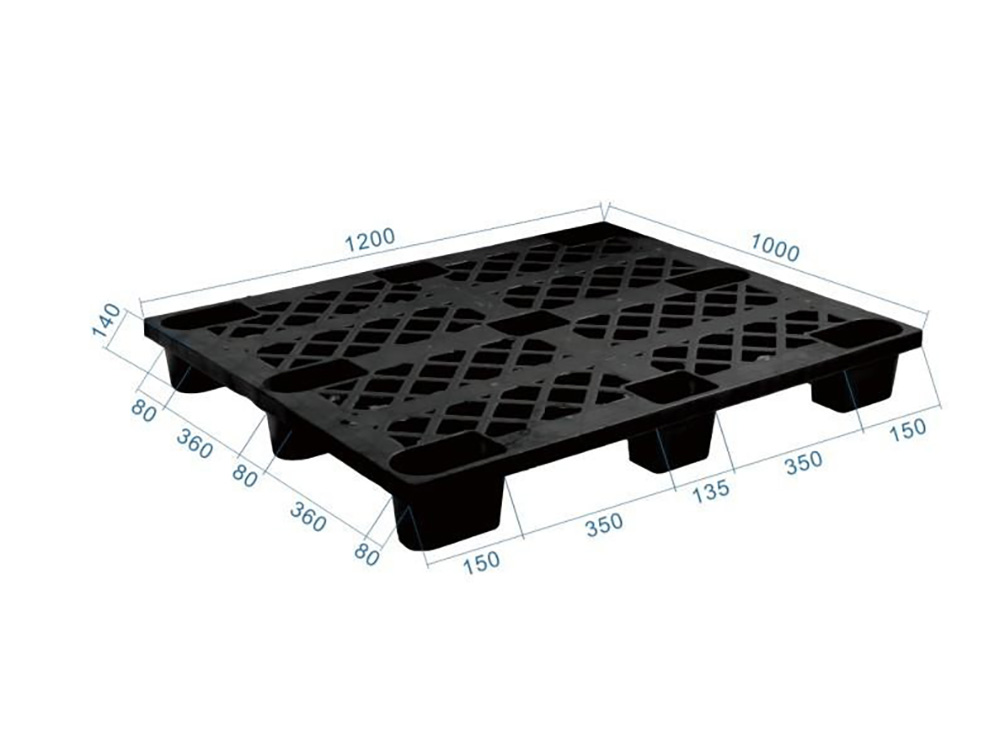

| A1/B1# | 1200 x 1000 x 140 | 500 KG | 1000 KG | Round Leg / Nestable |

| A2# | 1100 x 1100 x 140 | 600 KG | 1000 KG | Fork-entry Leg / Square |

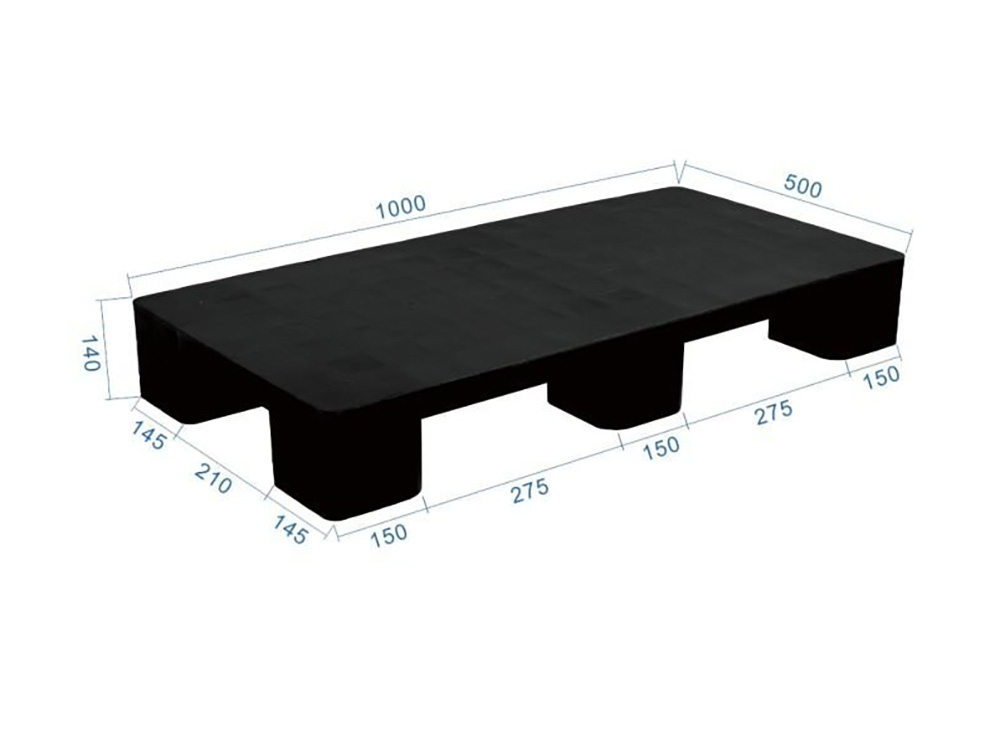

| A3# | 1200 x 1000 x 140 | 600 KG | 1000 KG | Fork-entry Leg / Standard |

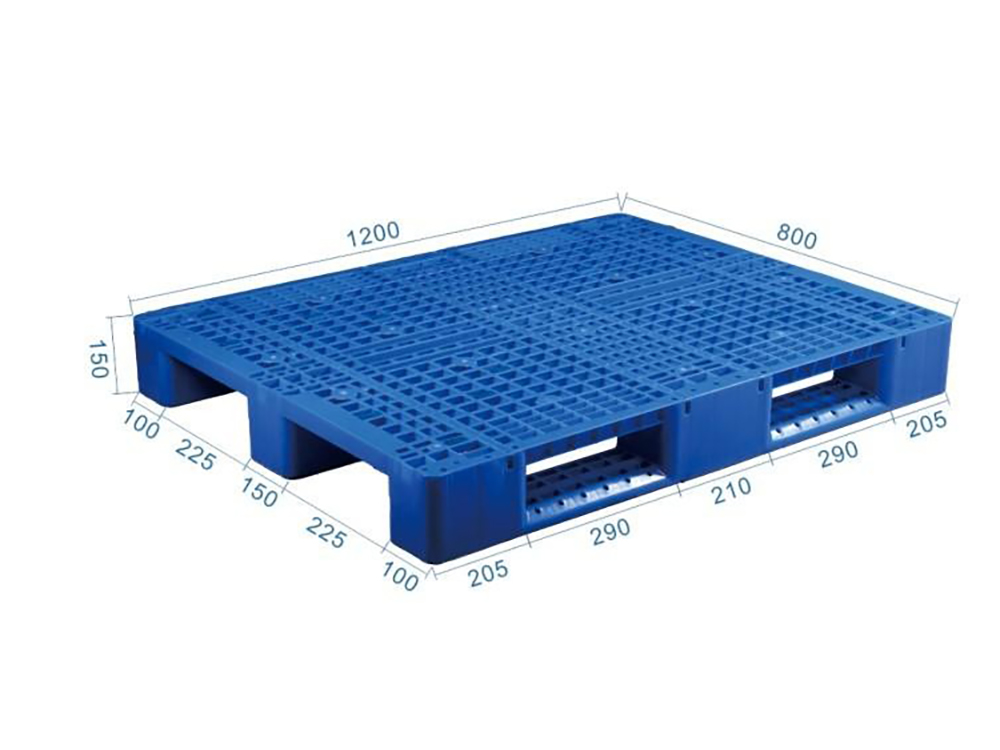

| 5# | 1200 x 800 x 140 | 300 KG | 800 KG | Slim / Round Leg |

🚀 Key Advantages

Why Choose Our 9-Leg ESD Plastic Pallets?

- Permanent Anti-Static Protection: Unlike coated pallets, our ESD properties are integrated into the material, ensuring a surface resistance of $10^4$ to $10^9$ Ohms that never fades.

- Space-Saving Nestable Design: The 9-leg structure allows pallets to nest inside each other when empty, reducing storage space by up to 60% and cutting return shipping costs.

- 4-Way Entry Compatibility: Optimized for both manual pallet jacks and forklifts, providing maximum flexibility in tight warehouse aisles.

- Cleanroom Ready: Made from high-density polyethylene (HDPE) with anti-static agents, these pallets are moisture-proof, easy to sanitize, and won't shed particles.

- Eco-Friendly & Durable: 100% recyclable and built to withstand rigorous industrial use without cracking or splintering.

🏭 Application Scenarios

Optimized for High-Tech Environments

- SMT & PCB Assembly: Safe transport of sensitive printed circuit boards and electronic modules.

- Semiconductor Manufacturing: Preventing electrostatic discharge in wafer fabrication and cleanroom environments.

- Automotive Electronics: Handling ECU units, sensors, and high-value electric vehicle (EV) components.

- Telecommunications: Storage of networking hardware and server components.

❓ Frequently Asked Questions

Common Inquiries About ESD Pallets

Q1: What is the typical surface resistance of your ESD plastic pallets? A: Our pallets typically fall within the conductive to dissipative range, maintaining a resistance of $10^4 \Omega$ to $10^9 \Omega$, compliant with ANSI/ESD S20.20 standards.

Q2: Can these pallets be used on high-level racking? A: The 9-leg series is primarily designed for floor storage and stackable transport. For high-level racking, we recommend our "3-Runner" (川字型) or "Full-Perimeter" (田字型) ESD pallets for better weight distribution.

Q3: Are these pallets resistant to chemicals? A: Yes, the HDPE material is highly resistant to most acids, alkalis, and industrial solvents, making them ideal for complex manufacturing environments.

Q4: Do you offer customization for specific sizes? A: We provide a variety of standard sizes (1210, 1111, 1208). For large-scale orders, custom molds and branding (logo embossing) are available.