Our Solid Top ESD plastic pallets are designed for environments where hygiene and static control are equally critical. Unlike traditional grid-style pallets, the flat, non-porous surface prevents dust, debris, and liquid from accumulating, making them the gold standard for cleanroom (ISO class) applications.

These flat-surface anti-static pallets provide a stable, smooth platform for transporting sensitive electronic assemblies, medical devices, and semiconductor wafers. With a permanent conductive path, they ensure that your high-precision products are shielded from the invisible threat of electrostatic discharge.

📊 Technical Specifications

Product Parameters

The Flat Surface series is optimized for specialized workstations and compact storage environments.

| Model No. | Dimensions (L×W×H mm) | Static Load | Design Type | Key Feature |

|---|---|---|---|---|

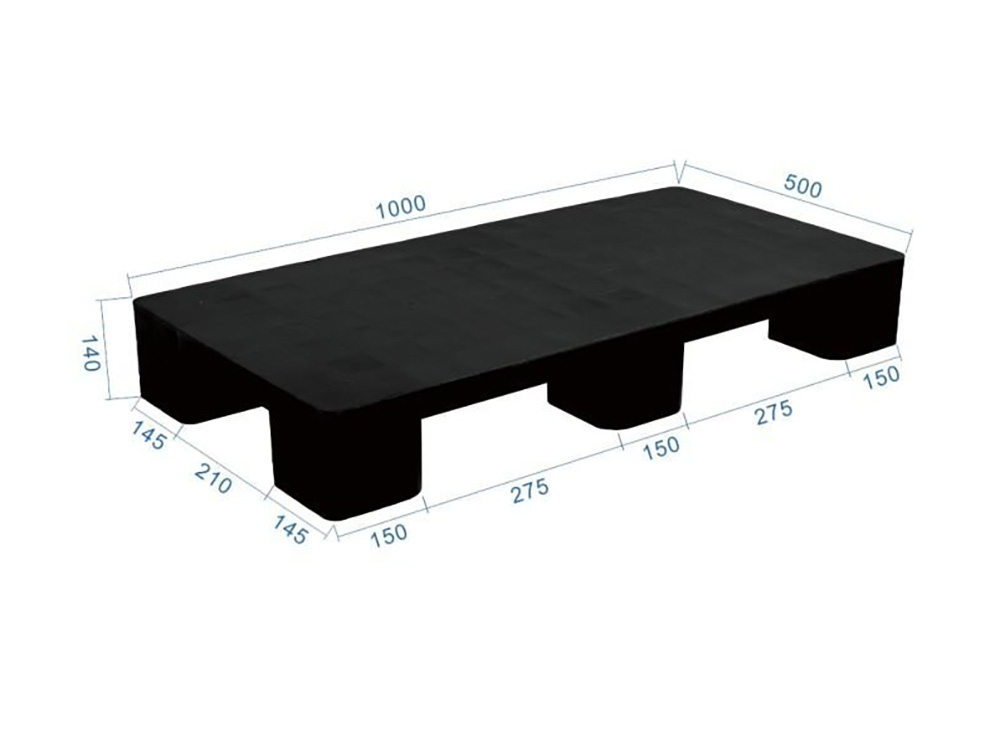

| 43# | 1000 x 500 x 140 | 1500 KG | 6-Leg Square Foot | Solid Top / Easy-Clean |

(Note: Custom sizes and dynamic load ratings are available upon request to meet your specific assembly line needs.)

🚀 Key Advantages

Why Choose Flat Surface ESD Pallets?

- Hygienic & Dust-Free: The solid deck eliminates "honeycomb" structures where dust and particles hide. It is the ideal choice for pharmaceutical electronics and semiconductor fabrication.

- Small Part Protection: The flat surface prevents small components, screws, or delicate tools from falling through mesh holes, reducing product loss and damage.

- Superior Cleanability: Can be easily wiped down or chemically sanitized without water trapping, ensuring compliance with strict cleanroom protocols.

- Uniform Static Dissipation: The solid material ensures a continuous and consistent surface resistance of 104−109Ω, providing a reliable "ground" for everything placed on the pallet.

- Compact & Versatile: The 1000x500mm footprint (Model 43#) is perfect for narrow aisles, laboratory workbenches, and specialized AGV (Automated Guided Vehicle) transport.

🏭 Application Scenarios

Optimized for Controlled Environments

- Semiconductor Cleanrooms: Transporting wafer boxes and sensitive lithography equipment.

- Medical Device Manufacturing: Handling static-sensitive diagnostic tools in sterile environments.

- Laboratory & Research: Providing a stable, anti-static work surface for delicate calibration and testing.

- Small-Scale Electronics Assembly: Ideal for compact SMT lines where space is at a premium and precision is paramount.

❓ Frequently Asked Questions

Expert Insights on Solid Top ESD Pallets

Q1: Why use a solid top pallet instead of a grid/mesh pallet? A: Solid top ESD pallets are preferred when hygiene is a priority. Grid pallets can trap dust and are harder to clean. Additionally, solid tops provide better support for very small items that might tilt or fall through the gaps of a mesh deck.

Q2: Can the flat surface be used as a temporary ESD workbench? A: Yes. Due to its stable 6-leg design and permanent anti-static properties, many facilities use these pallets as mobile, static-safe workstations for assembly or inspection tasks.

Q3: Is the surface slippery for electronic boxes? A: Our pallets feature a subtle matte finish or optional anti-slip textures that provide enough friction to keep boxes secure while remaining easy to clean.

Q4: How do I clean these pallets without damaging the ESD properties? A: You can use standard cleanroom IPA (Isopropanol) wipes or mild detergents. Since the ESD additive is integrated into the plastic resin, cleaning will not "wash away" the anti-static protection.