When stability and load-bearing capacity are non-negotiable, our Full-Perimeter ESD plastic pallets (also known as "Picture Frame" pallets) are the industry standard. Unlike the 9-leg design, the "田" shaped base provides a continuous surface contact, making them the superior choice for multi-tier stacking and use on conveyor systems.

Designed for the most demanding electronics manufacturing environments, these anti-static pallets prevent the accumulation of electrostatic charges, ensuring that your sensitive hardware—from semiconductors to automotive control units—remains protected throughout the supply chain.

📊 Technical Specifications

Product Parameters

Our Full-Perimeter series includes standard and specialized models to fit various global logistics requirements.

| Model No. | Dimensions (L×W×H mm) | Dynamic Load | Static Load | Design Type |

|---|---|---|---|---|

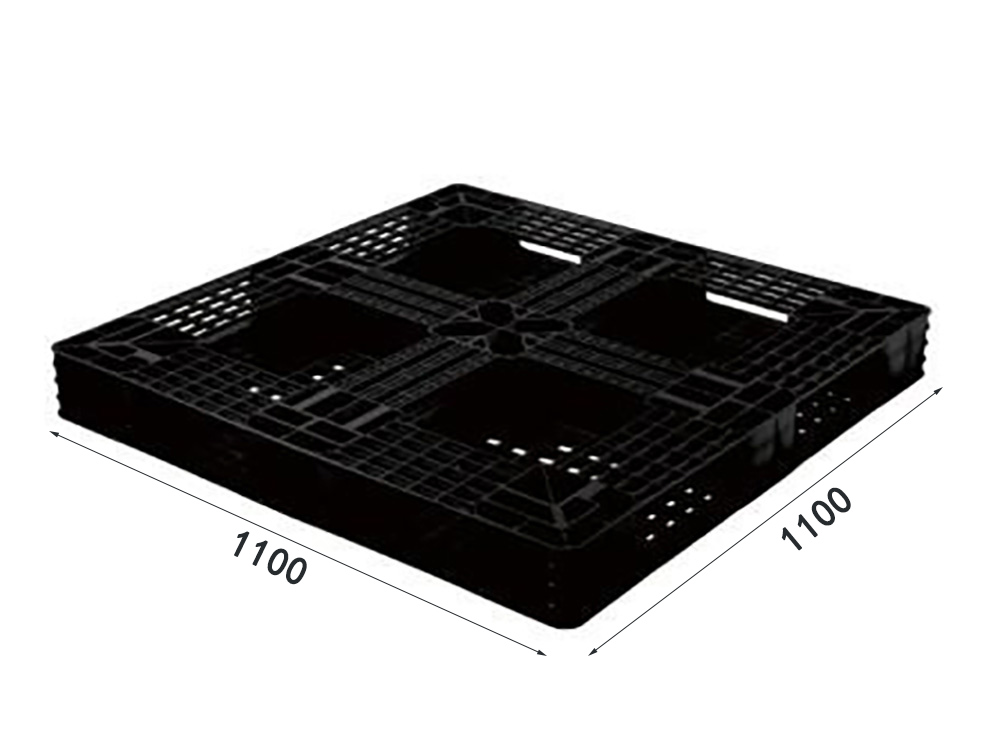

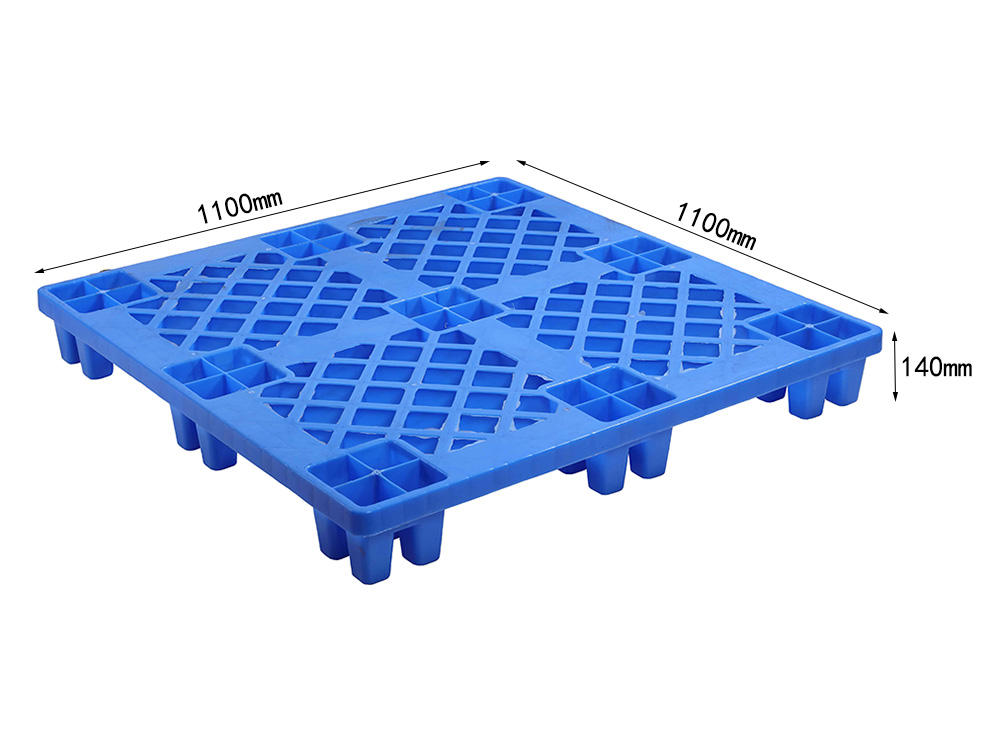

| 7# | 1100 x 1100 x 125 | 700 KG | 1500 KG | Low-Profile Full-Perimeter |

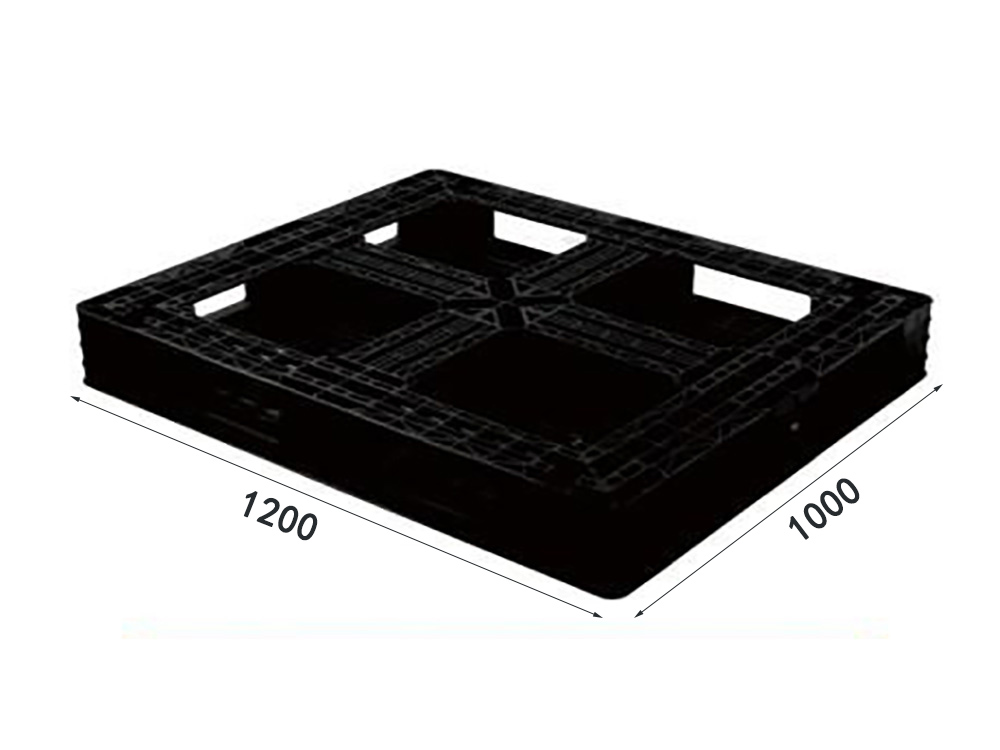

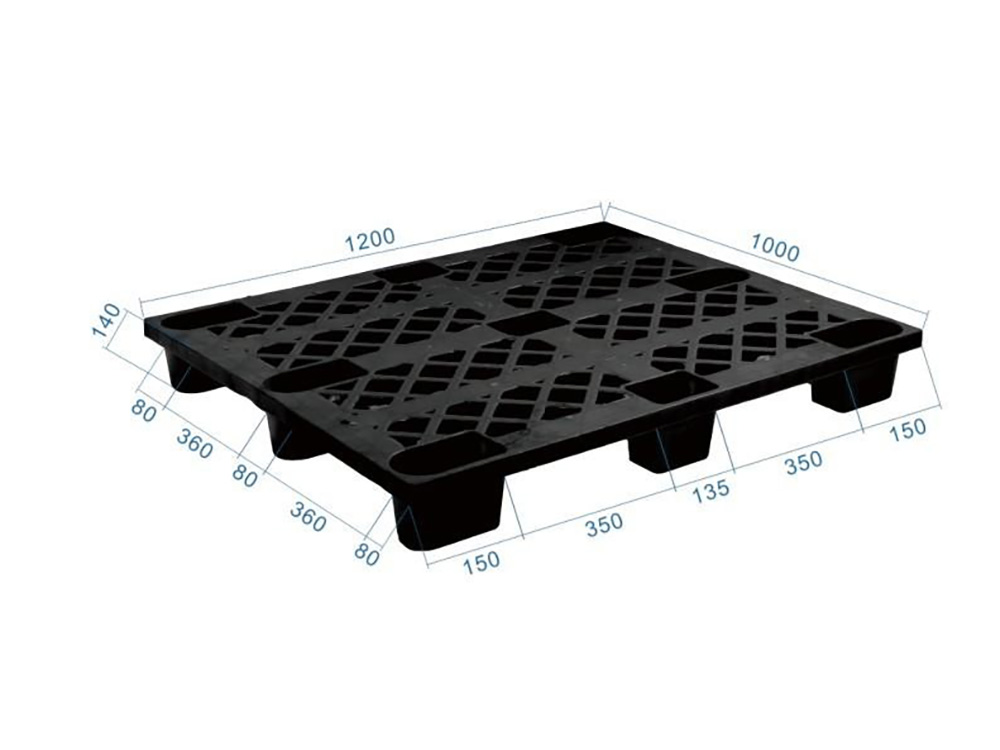

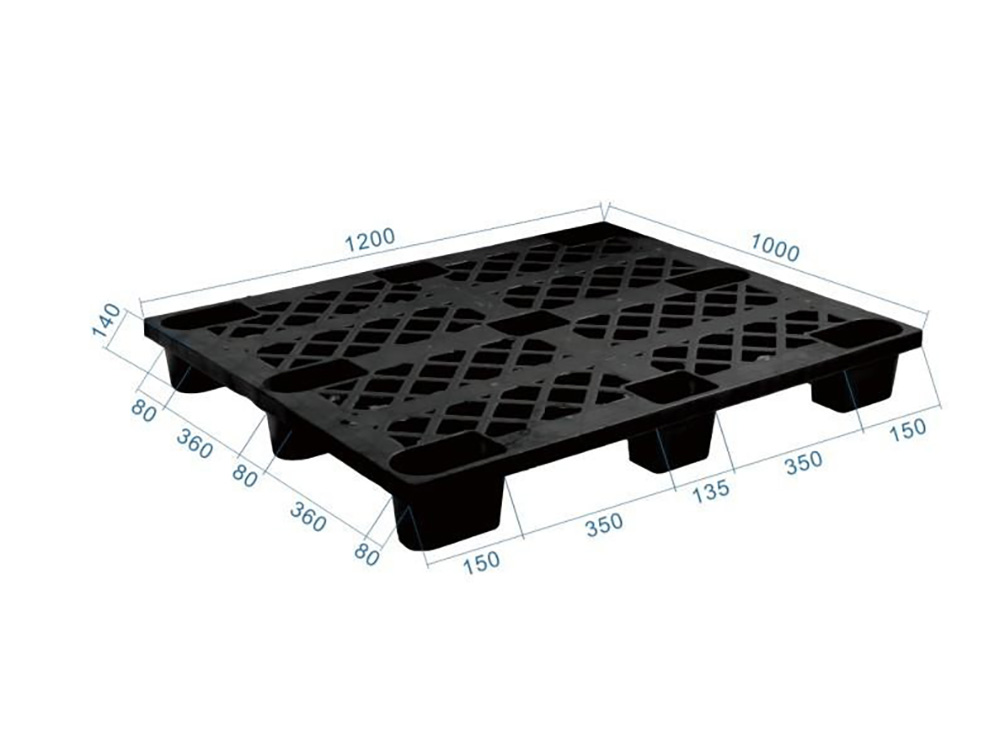

| 8# | 1200 x 1000 x 150 | 800 KG | 2000 KG | Standard Heavy-Duty |

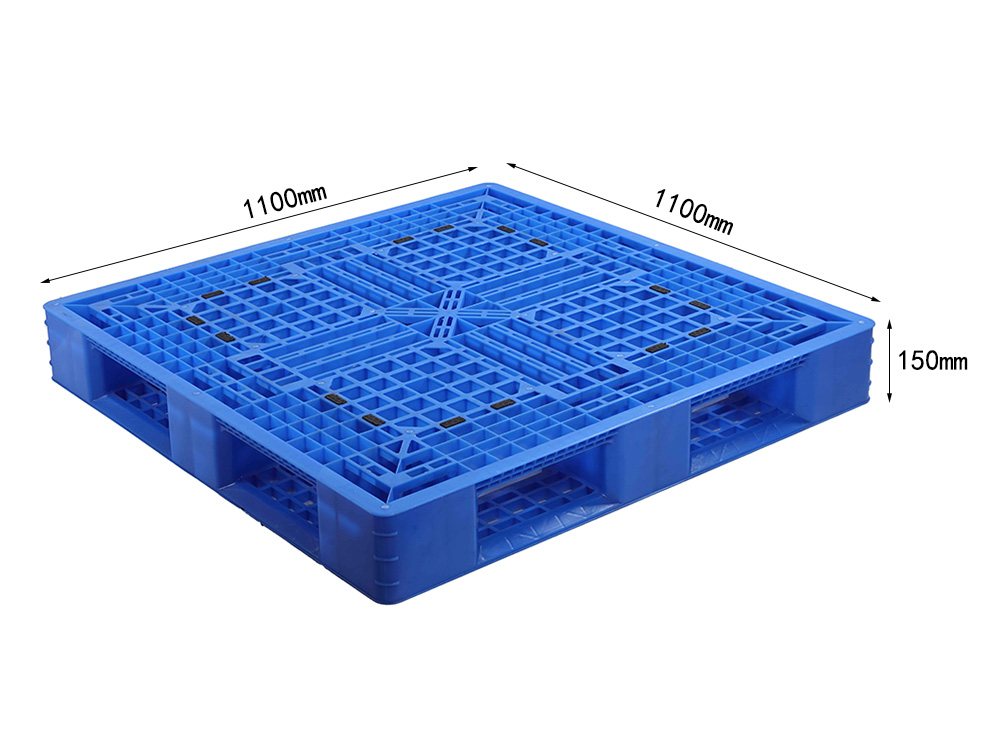

| 9# | 1100 x 1100 x 150 | 800 KG | 2000 KG | Square Heavy-Duty |

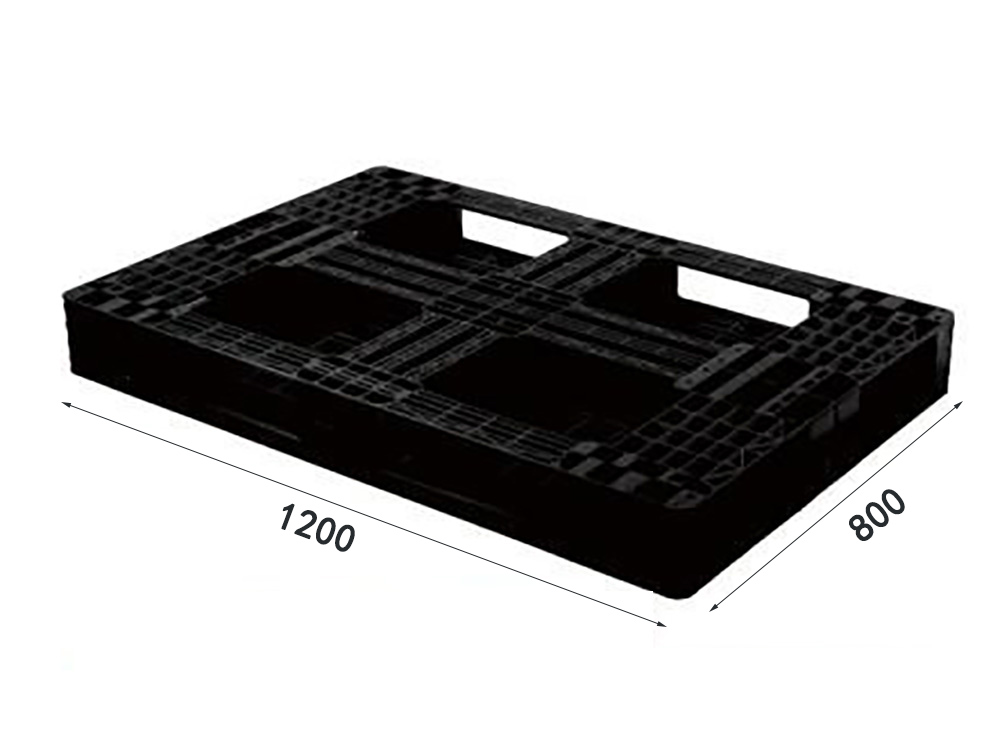

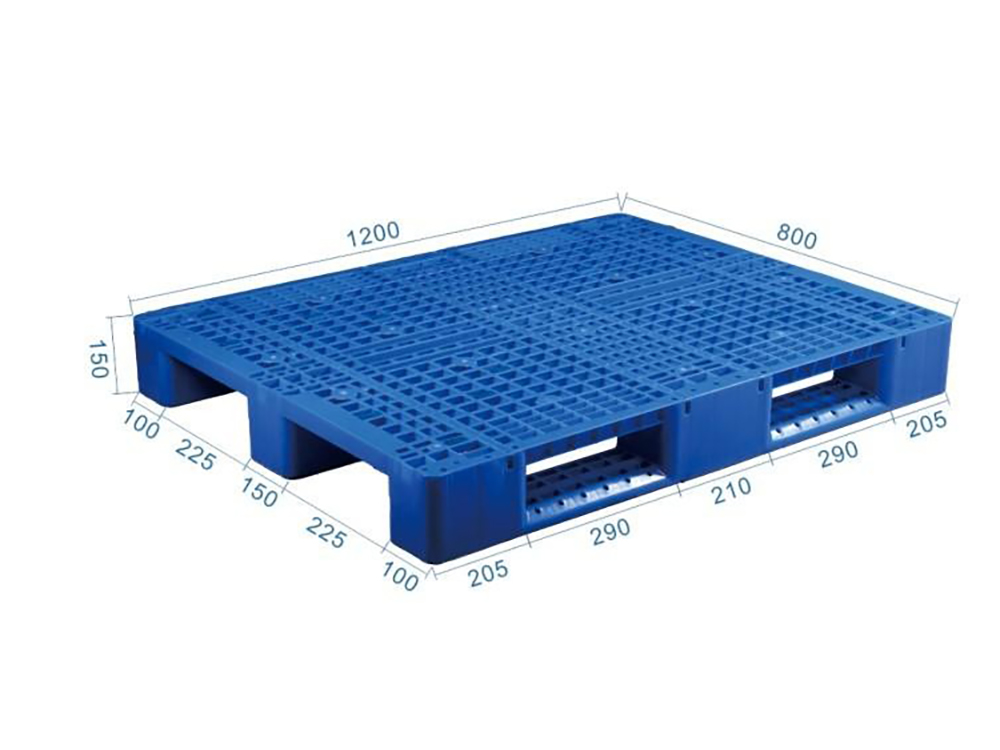

| A33# | 1200 x 800 x 140 | 700 KG | 1500 KG | Automotive Special (with slots) |

🚀 Key Advantages

Engineered for Stability and ESD Safety

- Superior Stacking Stability: The full-perimeter base distributes weight evenly, preventing damage to the goods below when stacking multiple layers high.

- Automated System Compatibility: The smooth, continuous bottom ensures seamless movement on roller conveyors and in automated storage and retrieval systems (AS/RS).

- Reliable Conductive Performance: Engineered with high-quality carbon black additives, providing a consistent surface resistance of $10^4 - 10^9 Omega$ to neutralize static risks.

- Reinforced Durability: Built for heavy-duty cycles, these pallets resist impact, moisture, and chemical corrosion better than wooden or standard plastic alternatives.

- Industry-Specific Features: Model A33# includes specialized positioning slots, making it the perfect ESD solution for automotive parts and precision machinery.

🏭 Application Scenarios

Where Performance Meets Protection

- Automated Warehousing: Perfect for high-tech distribution centers using conveyor belts and robotic pickers.

- Bulk Electronic Storage: Ideal for stacking boxed components like power supplies, monitors, and large PCB batches.

- Automotive Supply Chain: Specialized for transporting sensitive EV batteries and electronic control modules (ECUs).

- Heavy-Duty Industrial Use: Suitable for heavy electronic equipment that requires a stable, non-flexing base.

❓ Frequently Asked Questions

Expert Insights on Full-Perimeter ESD Pallets

Q1: Why choose a Full-Perimeter base over a 9-leg design? A: While 9-leg pallets are nestable and save space, Full-Perimeter (田字型) pallets offer much higher stability for stacking. If you need to stack pallets on top of each other, the full-perimeter base prevents the "point-loading" that can crush goods on the bottom pallet.

Q2: Are these pallets compatible with all types of forklifts? A: Yes, our series supports 4-way entry for forklifts. However, please note that due to the bottom runners, they are best suited for powered forklifts and specific types of pallet jacks designed for perimeter bases.

Q3: Does the anti-static property wear off over time? A: No. Our ESD plastic pallets feature "built-in" anti-static properties. The conductive material is blended into the plastic resin before molding, ensuring the protection lasts for the entire lifespan of the pallet.

Q4: Can the A33# model be used for international shipping? A: Absolutely. All our plastic pallets are ISPM-15 exempt, meaning they do not require fumigation for international export, saving you time and compliance costs.