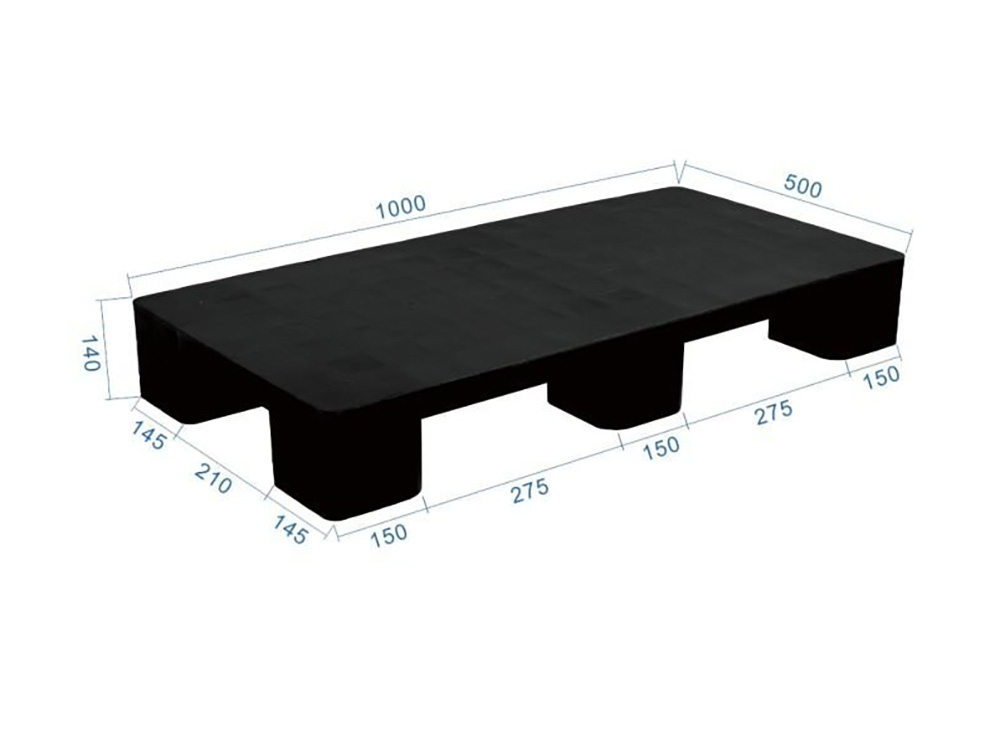

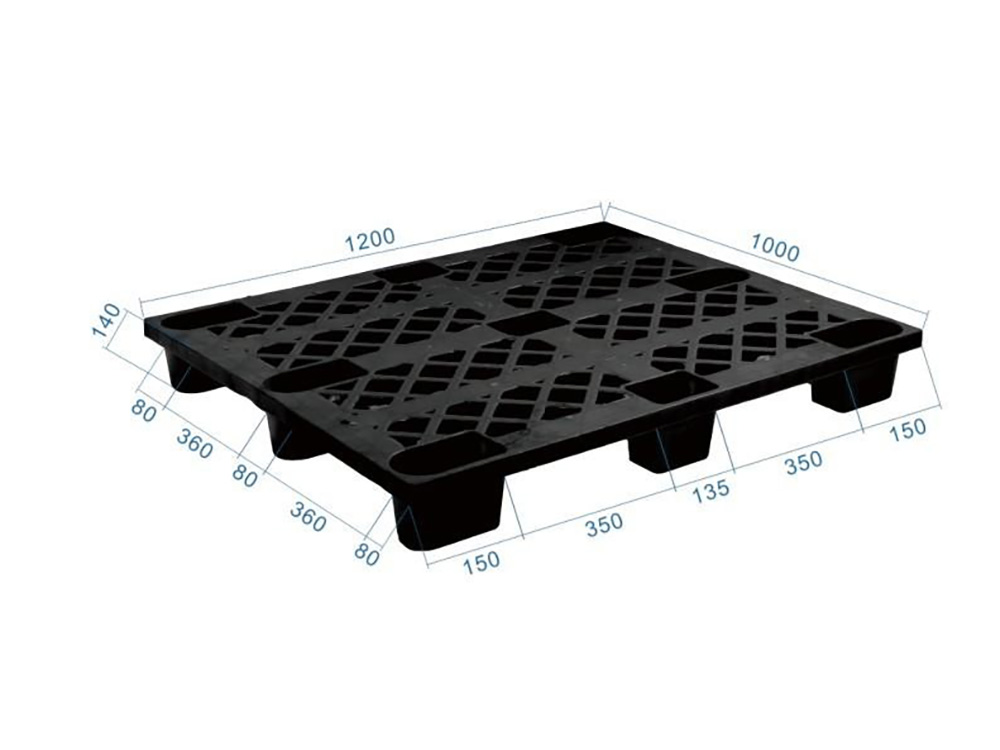

Our 3-runner ESD plastic pallets (also known as 3-skid pallets) are engineered for high-intensity logistics and high-bay racking systems. The "川" shaped base provides exceptional structural integrity, allowing the pallet to sit securely on rack beams without bending or slipping.

Specifically developed for the electronics, semiconductor, and telecommunications industries, these ESD plastic pallets offer a consistent discharge path to protect sensitive equipment from static-related failures. With the option for internal steel tube reinforcement, these pallets are the heavy-duty workhorses of the anti-static storage world.

📊 Technical Specifications

Product Parameters

The 3-runner series is characterized by its high load capacity and compatibility with various handling equipment.

| Model No. | Dimensions (L×W×H mm) | Dynamic Load | Static Load | Key Feature |

|---|---|---|---|---|

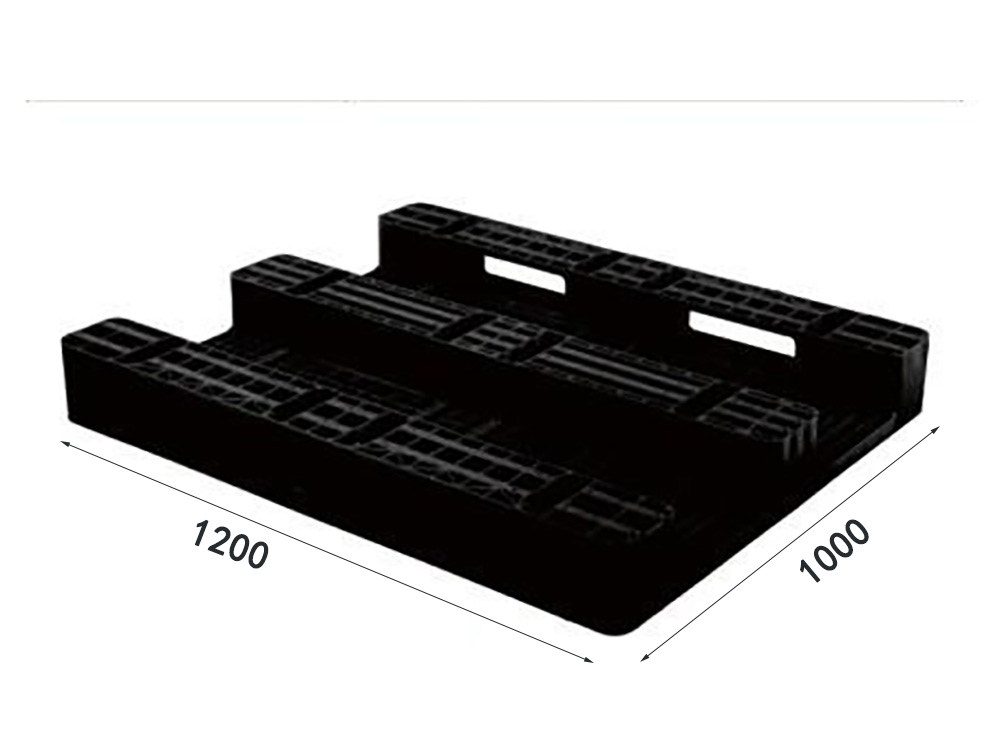

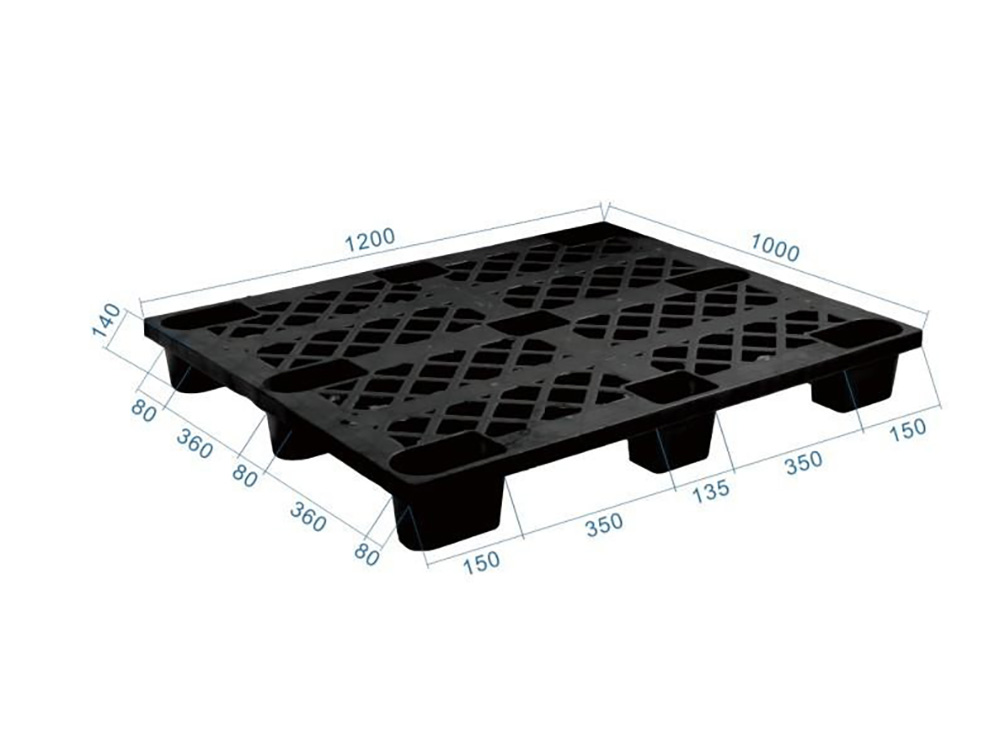

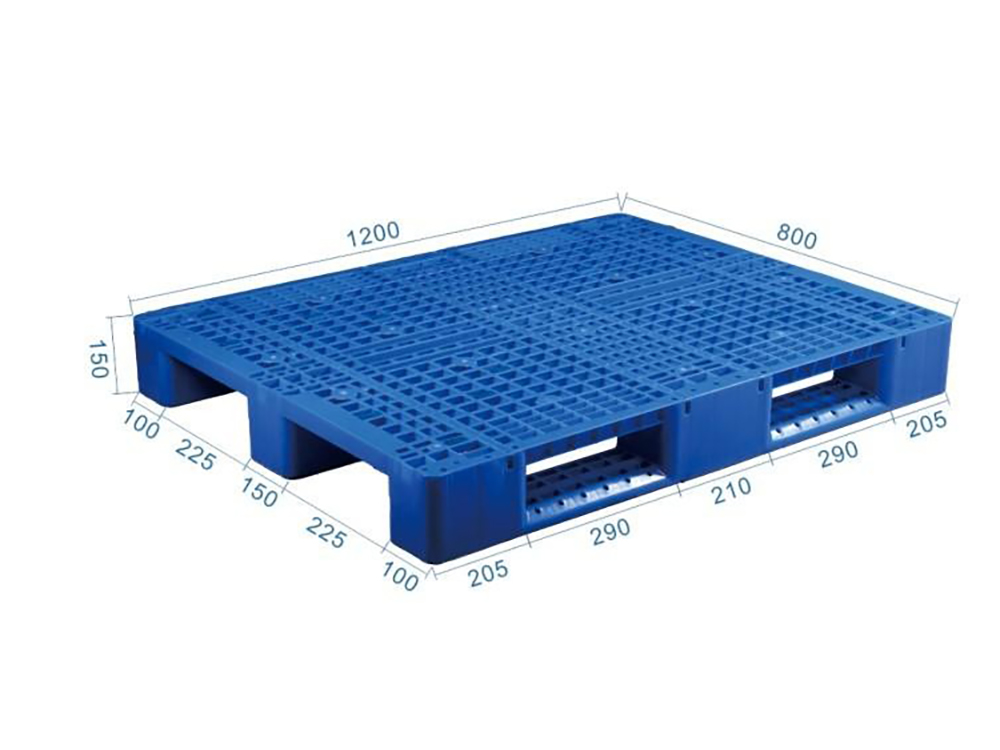

| 10# | 1200 x 1000 x 150 | 800 KG | 2000 KG | 3 Steel Tubes Optional |

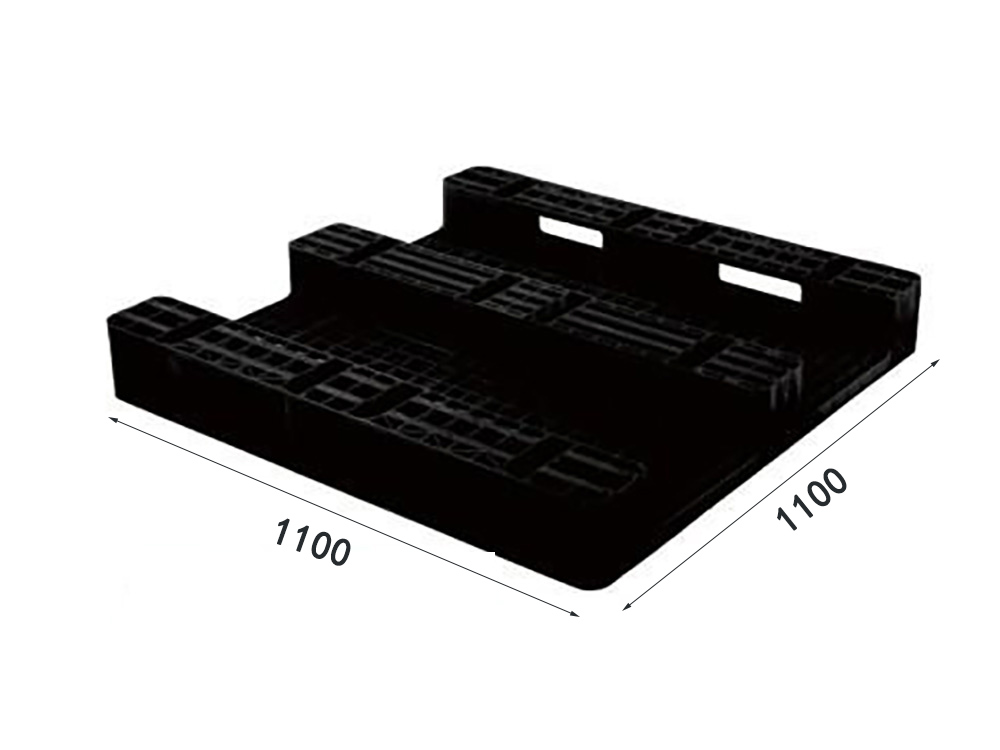

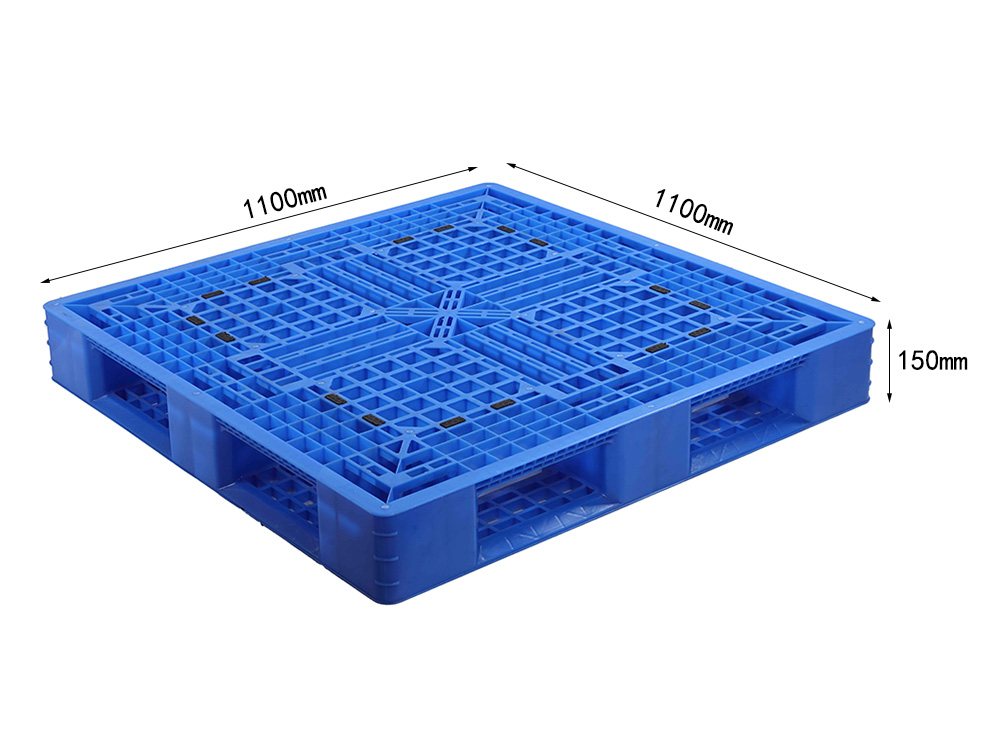

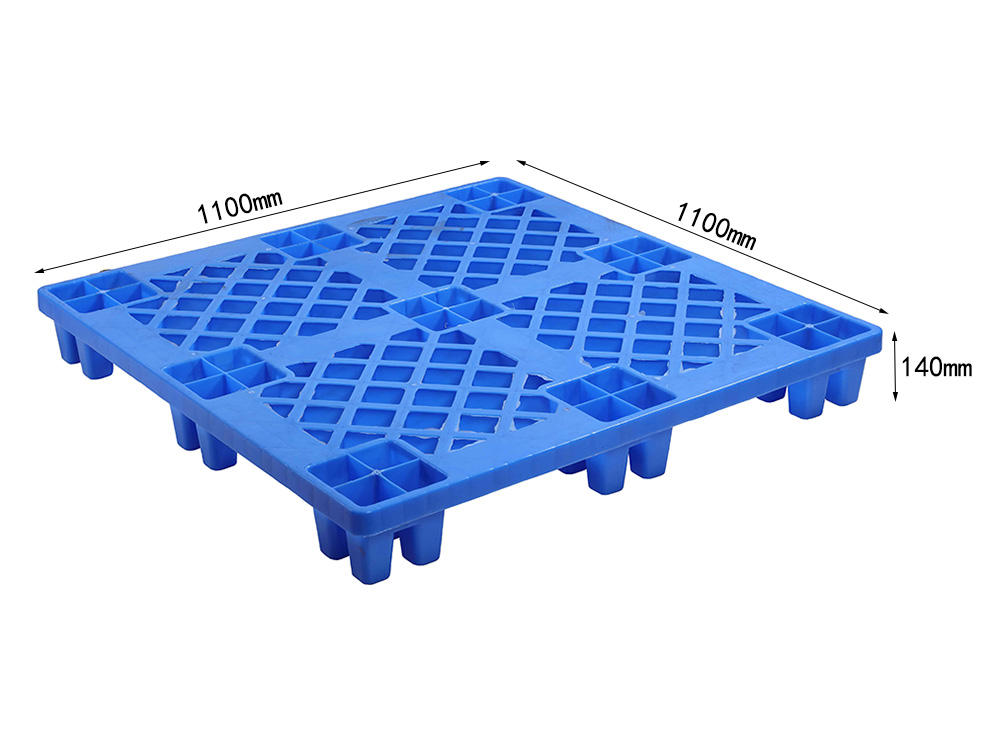

| 24# | 1100 x 1100 x 150 | 1000 KG | 2500 KG | Up to 10 Steel Tubes |

| 27# | 1200 x 1000 x 150 | 1000 KG | 2500 KG | High-Load Racking Pro |

🚀 Key Advantages

Optimized for High-Bay Storage & ESD Safety

- Rack-Ready Design: The 3-runner base is specifically designed to span warehouse rack beams, offering superior safety and stability for overhead storage.

- Steel Tube Reinforcement: Models like 24# and 27# can be reinforced with internal steel tubes, significantly increasing the "Rack Load" capacity and preventing long-term deformation.

- Permanent ESD Protection: Utilizing advanced conductive resins, our pallets maintain a surface resistance of 104−109Ω, ensuring that static is safely dissipated away from your components.

- Excellent Forklift Access: Features a 4-way entry for forklifts and a 2-way entry for pallet jacks, making it highly versatile for both transport and storage.

- Hygienic & Durable: The grid-top design allows for airflow and easy cleaning, while the HDPE material is resistant to moisture, chemicals, and extreme temperatures.

🏭 Application Scenarios

Built for Industrial-Scale Electronics Logistics

- High-Bay Racking Systems: The primary choice for electronics distribution centers using vertical space.

- Heavy Equipment Transport: Safe handling of large server racks, industrial power units, and heavy PCB testing machinery.

- Automated Production Lines: Compatible with chain conveyors and automated palletizers used in smart factories.

- Long-Term Bulk Storage: Providing a static-safe environment for high-value inventory in climate-controlled warehouses.

❓ Frequently Asked Questions

Common Questions on 3-Runner ESD Pallets

Q1: What makes the 3-runner design better for racking than other types? A: The three parallel runners provide a stable "bridge" across rack beams. This structure minimizes the risk of the pallet falling through the rack and allows for higher weight distribution compared to 9-leg designs.

Q2: How many steel tubes can be added to the 27# model? A: The 27# model can accommodate up to 10 internal steel tubes, which drastically enhances its load-bearing performance, especially for "on-the-rack" applications where the pallet is only supported at the edges.

Q3: Is the anti-static performance affected by humidity? A: No. Our ESD plastic pallets use carbon-based conductive additives rather than humidity-dependent chemical coatings. This ensures reliable anti-static performance in both dry and humid warehouse conditions.

Q4: Can these pallets be used with automated conveyor belts? A: Yes, the 3-runner design is highly compatible with chain and roller conveyors commonly found in automated logistics systems.