1. Material

Made from high-quality HDPE (High-Density Polyethylene), these pads are hard-wearing, moisture-proof, and odorless. They are suitable for direct contact with goods, including food-grade applications, ensuring a clean and safe environment for stored items.

2. Usage Scenarios

These versatile pads and skids are engineered to enhance protection, stability, and organization across various industrial and commercial settings:

- Moisture Barrier: Placed directly on floors or existing pallets to prevent rising dampness from damaging cartons or bagged goods, protecting inventory integrity.

- Floor Protection: Heavy-duty mats protect warehouse floors from damage caused by forklifts and heavy machinery while providing anti-slip surfaces for safety.

- Cargo Divider / Layer Sheets: Used as layer sheets between stacked goods to stabilize the load, prevent shifting, and improve overall space utilization within containers or storage racks.

- Tile Adhesive Mat: The specialized Pad 11# is specifically designed for construction sites, offering resistance to compression and an easy-to-clean surface for machinery like tile adhesive machines.

3. Key Specifications

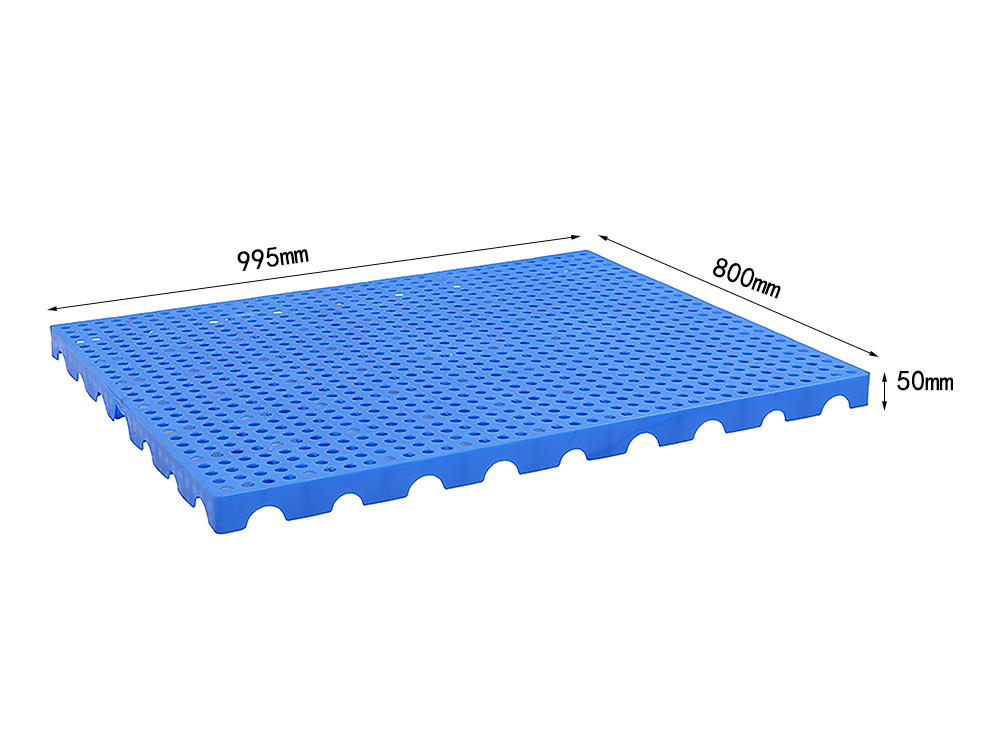

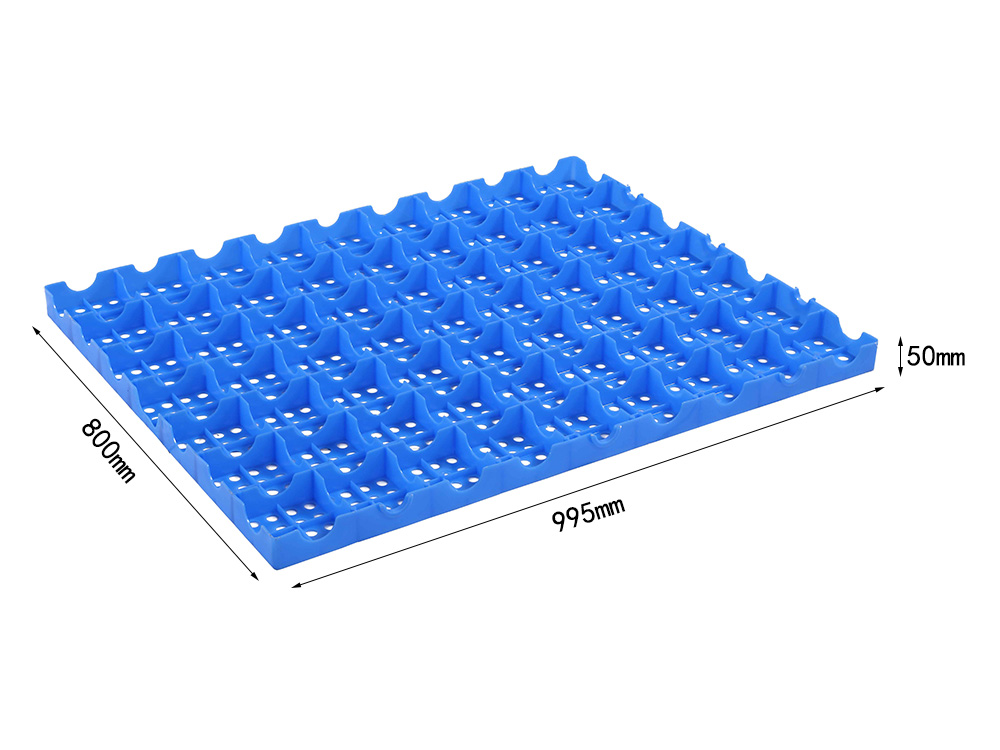

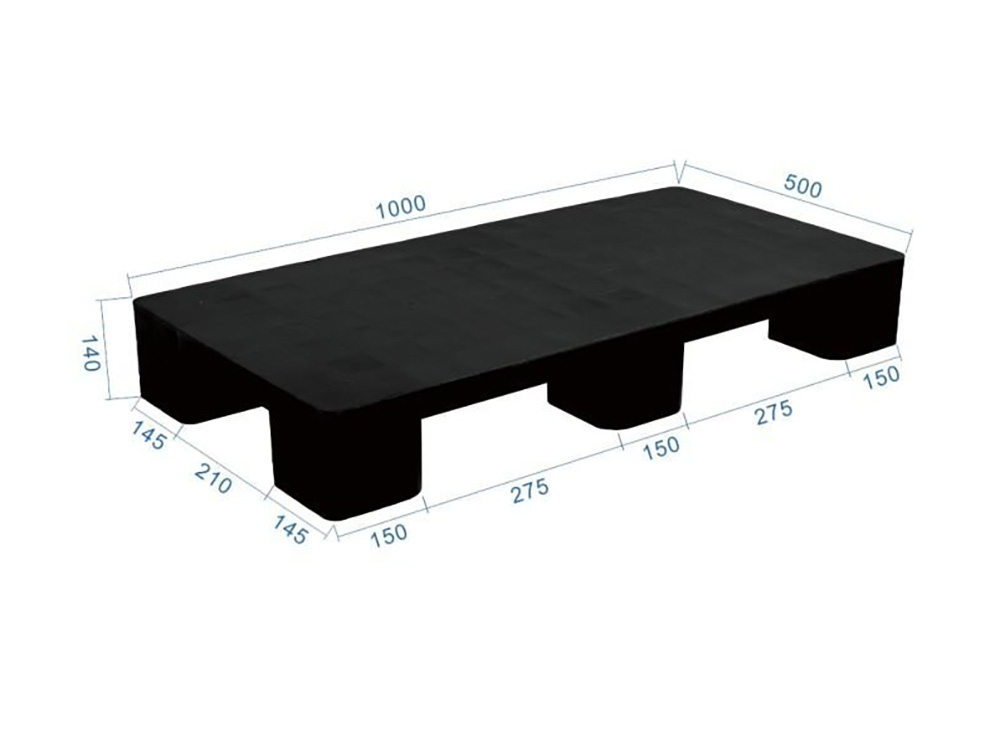

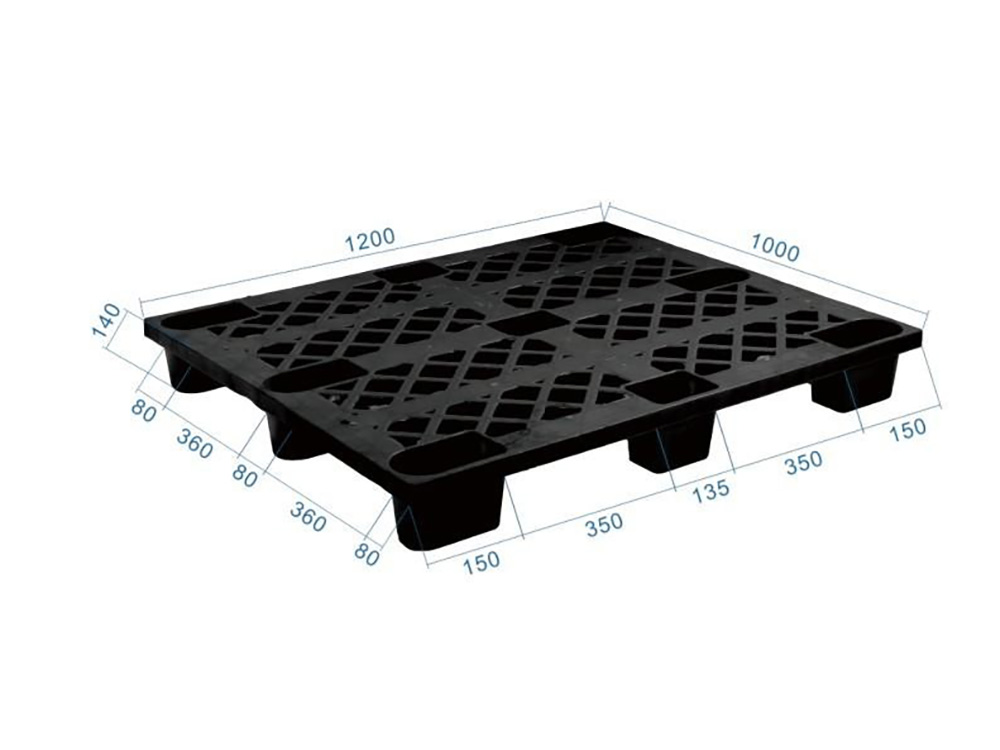

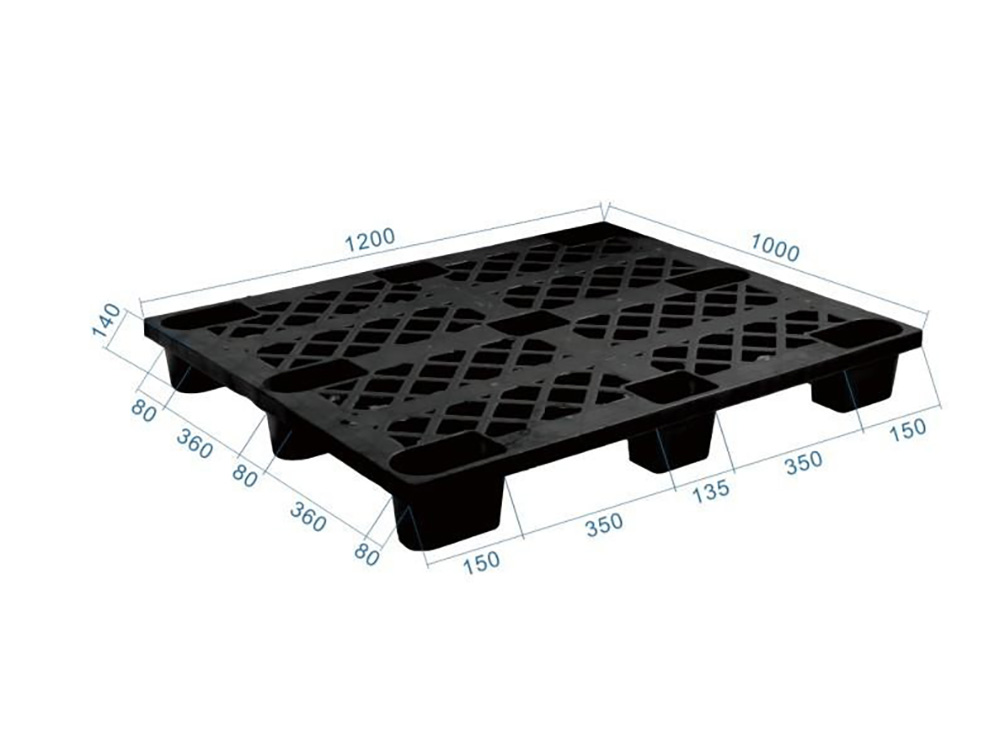

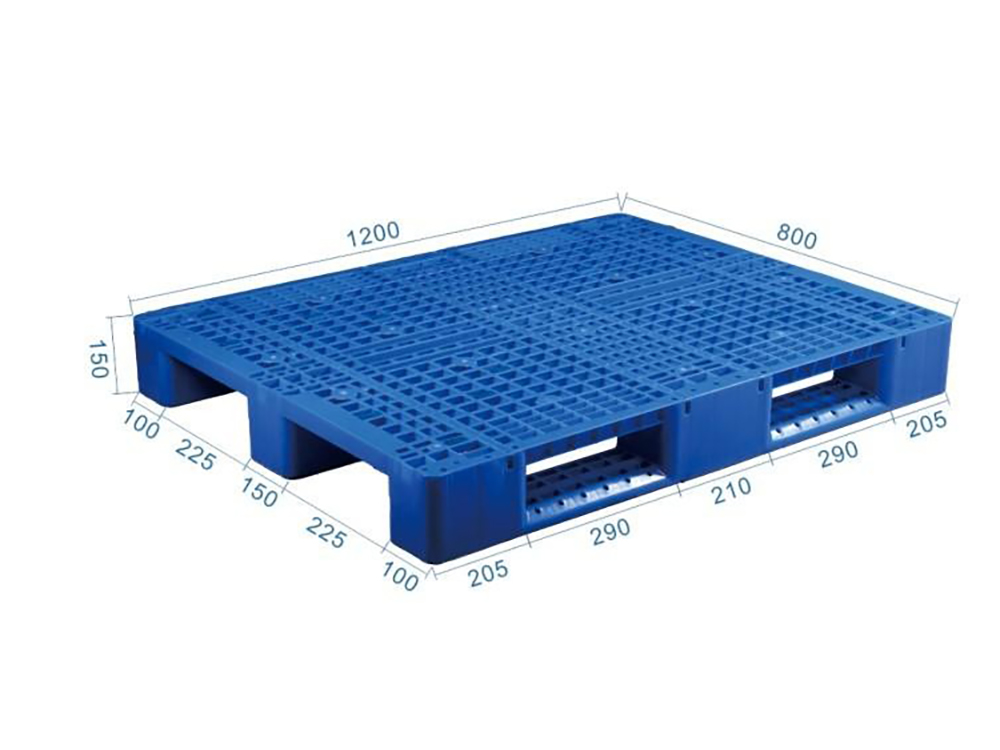

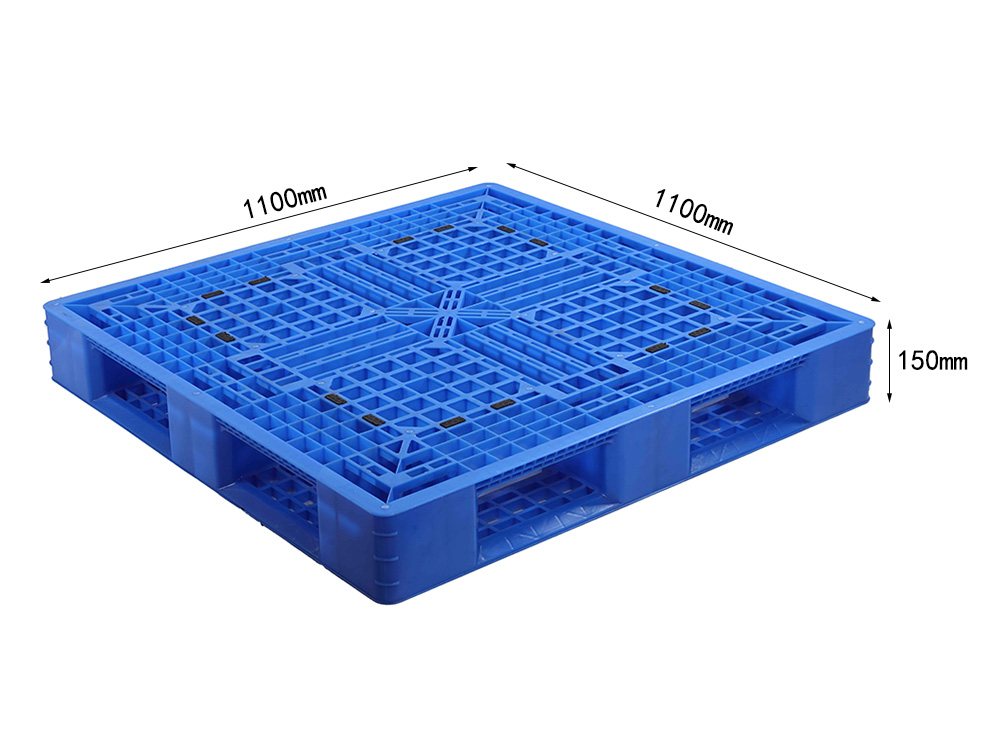

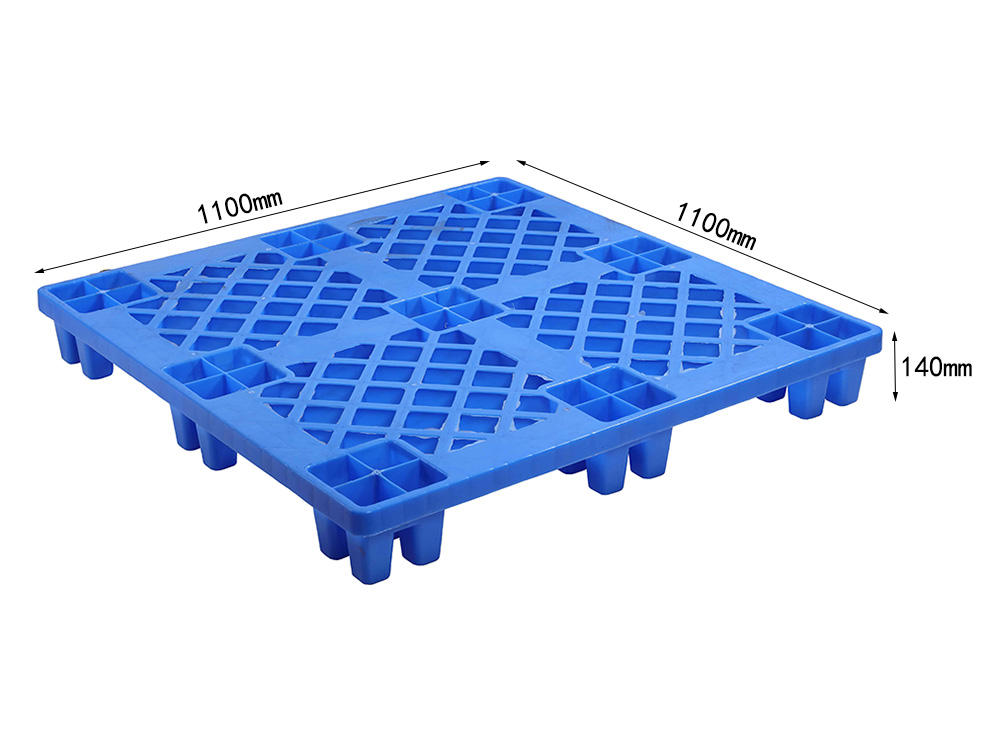

Dimensions are listed as Length x Width x Thickness/Height (L x W x H) in millimeters (mm).

| Model | Size (mm) (L×W×H) | Typical Use |

|---|---|---|

| Pad 1# | 1000 × 800 × 50 | General moisture-proof pad, separator pad (standard pallet size) |

| Pad 2# | - | General moisture-proof pad, separator pad (customizable size) |

| Pad 3# | 900 × 300 × 50 | Small goods moisture protection, floor protection |

| Pad 4# | 600 × 300 × 50 | Small goods moisture protection, separator pad |

| Pad 5# | 710 × 440 × 30 | Light-duty moisture-proof pad, temporary floor covering |

| Pad 6# | 300 × 300 × 30 | Small parts / bagged goods moisture protection |

| Pad 7# | 400 × 400 × 30 | General moisture-proof pad for small items |

| Pad 8# | 500 × 500 × 30 | Medium-size goods moisture-proof pad and separator |

| Pad 9# | 600 × 600 × 30 | Medium-size goods pad, temporary work surface |

| Pad 10# | 1000 × 600 × 100 | Heavy-duty floor protection and moisture-proof pad (extra thick) |

| Pad 11# (tile machine pad) | 450 × 350 × 140 | Tile adhesive machine pad, construction use (specialized height/thickness) |

4. Frequently Asked Questions (FAQ)

Q1: What is the primary benefit of using HDPE for these pads?

A: HDPE is chosen for its superior properties: it is non-porous (excellent moisture-proofing), highly resistant to impact and chemicals (hard-wearing), and safe for contact with food and other sensitive goods (odorless and non-toxic).

Q2: How do these pads function as a moisture barrier?

A: When placed directly on a concrete floor, the non-porous HDPE pad creates a physical barrier that prevents moisture rising from the floor (known as capillary action) from reaching and damaging the goods stacked above.

Q3: What is the difference between a "moisture-proof pad" and a "separator pad"?

A:

- Moisture-proof pad: Primarily used on the floor or under a pallet to prevent dampness.

- Separator pad (Layer Sheet): Used between layers of stacked products (e.g., between boxes) to distribute weight evenly, stabilize the load, and prevent crushing or shifting.

Q4: Why is the size for Pad 2# missing?

A: The missing size for Pad 2# is intentional, as the "Typical Use" note indicates it is a customizable general moisture-proof and separator pad. This model is likely offered in custom dimensions tailored to a client's specific requirements, unlike the fixed sizes of the other models.

Q5: Which pad is recommended for the heaviest applications?

A: The Pad 10# (1000 x 600 x 100 mm) is explicitly designated for "Heavy-duty floor protection and moisture-proof pad." Its 100 mm thickness makes it the most robust option for high-impact or extremely heavy-load environments.