The Foundation of Modern Logistics: High-Performance Plastic Pallets

In the world of warehousing, a pallet isn't just a platform—it’s the backbone of your entire supply chain. Our professional-grade plastic pallets are engineered from premium High-Density Polyethylene (HDPE) and Polypropylene (PP) to solve the common headaches of traditional wood: splinters, rot, and inconsistent sizing.

Whether you are navigating the strict hygiene requirements of the pharmaceutical industry or the heavy-duty demands of automotive manufacturing, these pallets offer a "one-and-done" solution. They are 100% waterproof, impact-resistant, and fully recyclable, making them as good for your bottom line as they are for the planet.

✨ Engineered for Performance: Key Features

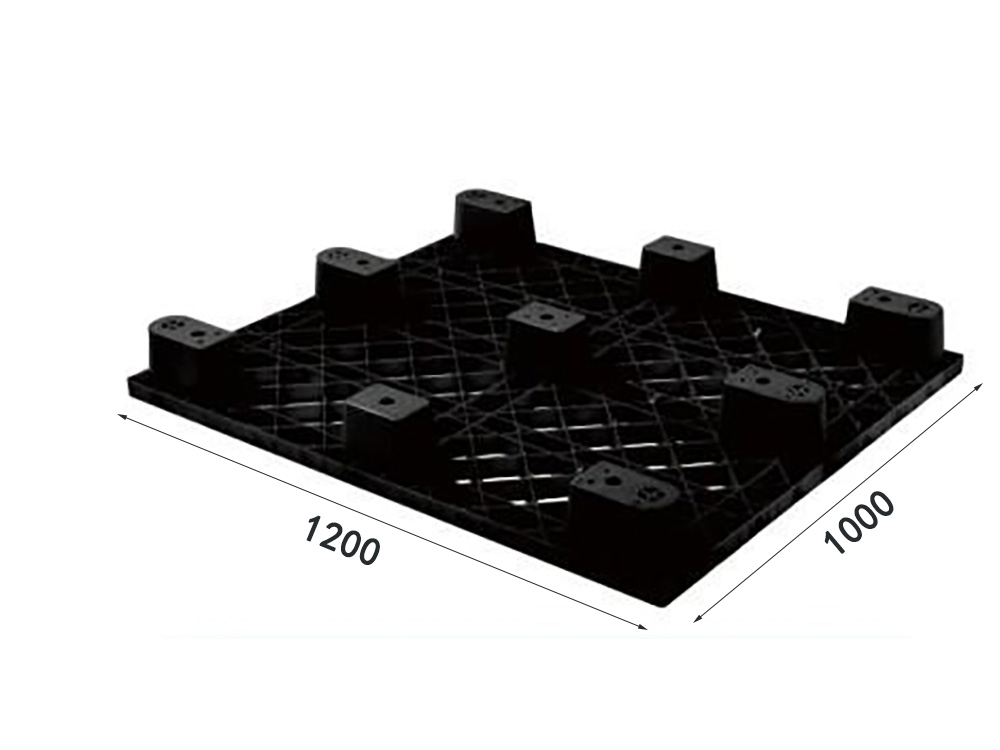

- Reinforced Structural Integrity: We don't just rely on plastic. Selected heavy-duty models feature built-in steel tubes, drastically increasing racking load capacity and preventing "bowing" under long-term stress.

- Industry-Specific Solutions: From ESD-safe (Anti-Static) series for electronics to the A33# Grid Pallets with specialized hooks for the automotive sector, we build for your specific workflow.

- Thermal Resilience: Designed to perform in extreme environments, our pallets maintain structural integrity in temperatures ranging from -20℃ to 60℃, making them the gold standard for cold chain logistics.

- Color-Coded Efficiency: While Blue, Black, and Gray are our standard, we offer full customization (Red, Yellow, Green) for bulk orders to help you implement visual warehouse management systems.

📊 Technical Specifications: Finding Your Perfect Match

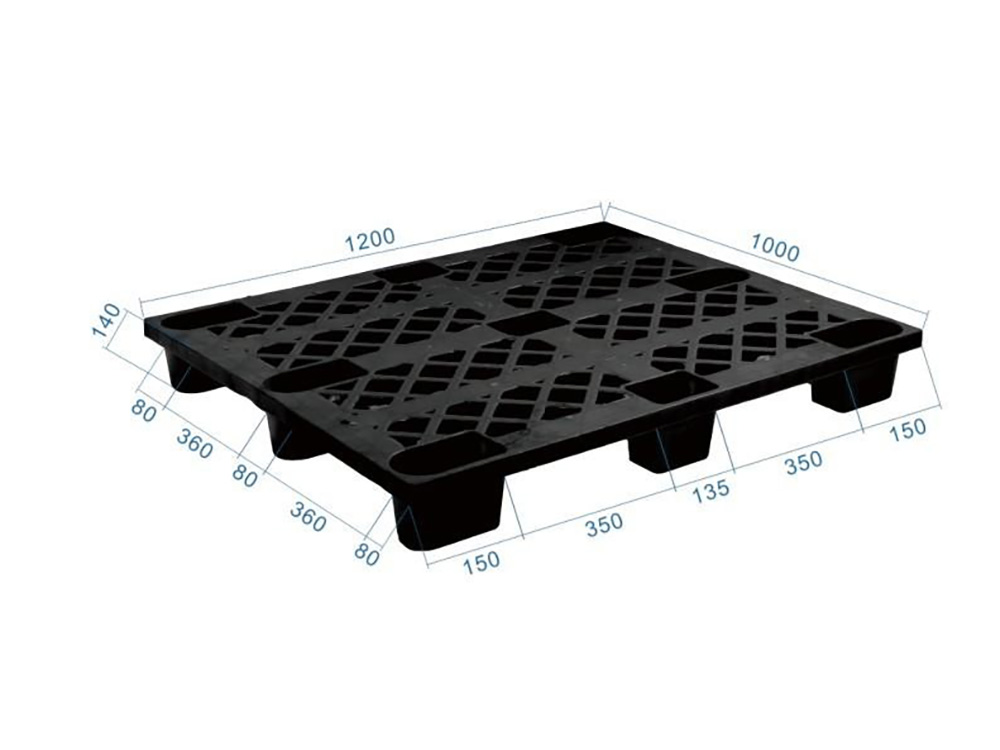

| Model | Description / Type | Size (mm) | Dynamic Load | Static Load |

|---|---|---|---|---|

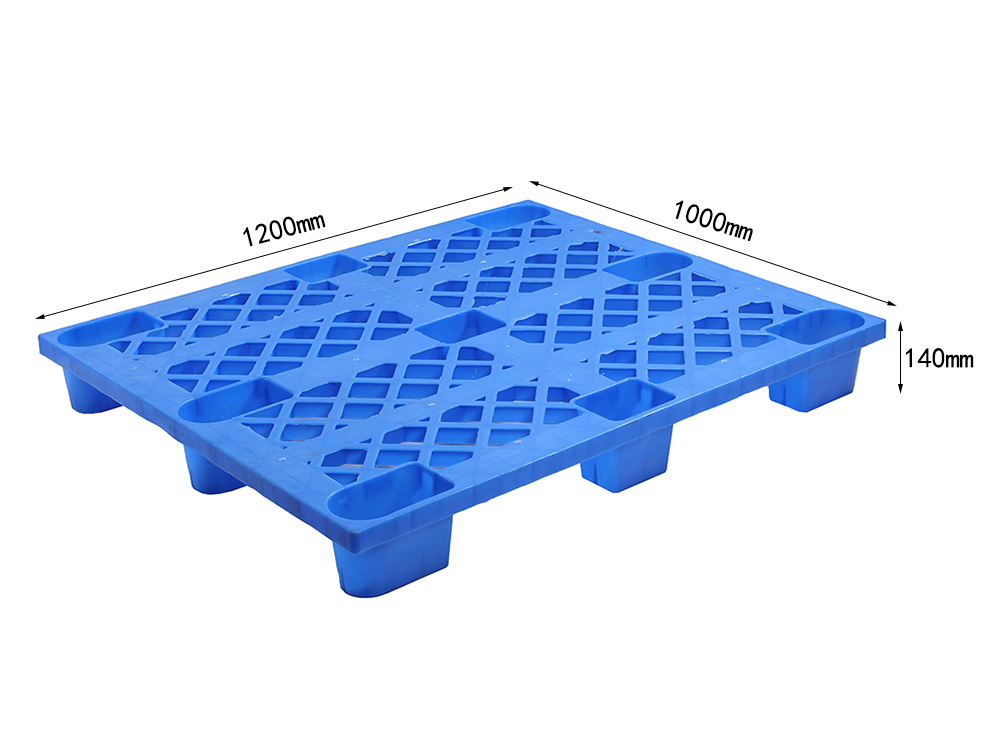

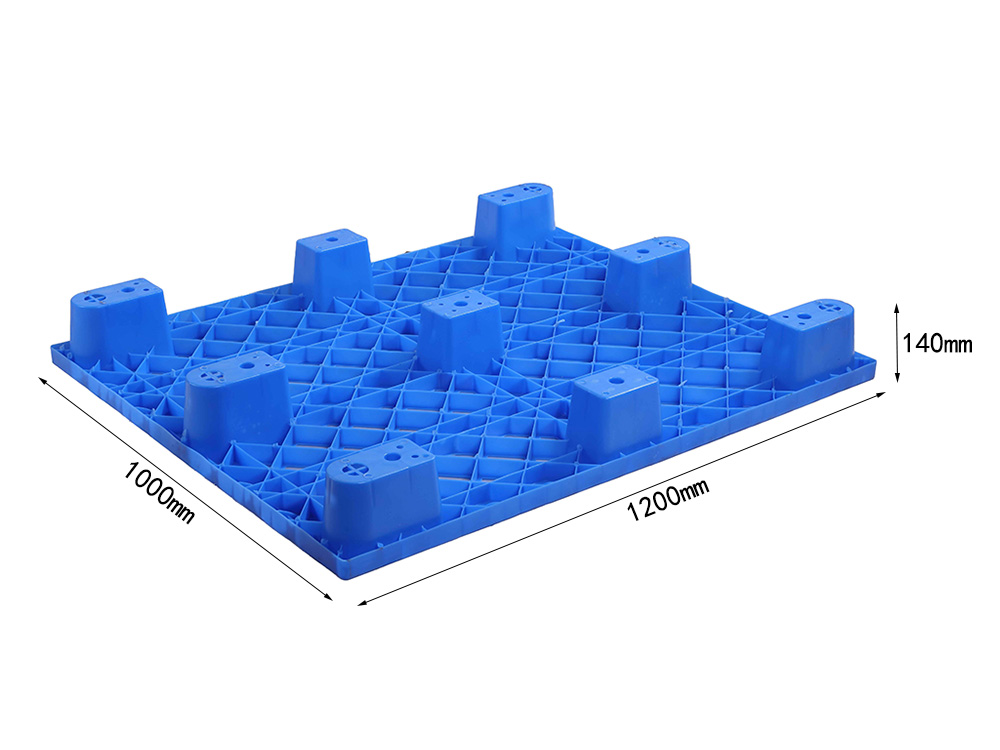

| A1# | Single-sided - Round Foot | 1200 x 1000 x 140 | 500 KG | 1000 KG |

| B1# | Single-sided - Round Foot | 1200 x 1000 x 140 | 400 KG | 1000 KG |

| DYC1# | Single-sided - Round Foot | 1200 x 1000 x 145 | 300 KG | 800 KG |

| A4# | Single-sided - Round Foot | 1000 x 1000 x 145 | 400 KG | 1000 KG |

| 5# | Single-sided - Round Foot | 1200 x 800 x 140 | 300 KG | 800 KG |

| 53# | Single-sided - Round Foot | 1200 x 1100 x 145 | 600 KG | 1200 KG |

| 4# | Single-sided - Round Foot | 1100 x 1100 x 125 | 700 KG | 1500 KG |

| 7# | Grid Pallet - Full Perimeter Base | 1300 x 1100 x 145 | 700 KG | 1300 KG |

| 8# | Grid Pallet - Full Perimeter Base | 1200 x 1000 x 150 | 800 KG | 2000 KG |

| A2# | Single-sided - Fork Foot | 1100 x 1100 x 140 | 600 KG | 1000 KG |

| A3# | Single-sided - Fork Foot | 1100 x 1100 x 150 | 800 KG | 2000 KG |

| 9# | Grid Pallet - Full Perimeter Base | 1200 x 1000 x 140 | 600 KG | 1000 KG |

| 47# | Single-sided - Fork Foot | 1100 x 1100 x 150 | 1000 KG | 2500 KG |

| A9# | Grid Pallet - Full Perimeter Base | 1200 x 1200 x 150 | 600 KG | 1200 KG |

| 14# | Grid Pallet - Full Perimeter Base | 1200 x 1000 x 125 | 700 KG | 1500 KG |

| 13# | Grid Pallet - 3-Runner Base | 1300 x 1100 x 150 | 1000 KG | 2500 KG |

| 15# | Grid Pallet - Full Perimeter Base | 1300 x 1100 x 150 | 1000 KG | 2000 KG |

| 20# | Grid Pallet - 3-Runner Base | 1200 x 1000 x 150 | 800 KG | 2000 KG |

| A33# | Grid Pallet - Full Perimeter Base | 1200 x 800 x 140 | 700 KG | 1500 KG |

| 21# | Grid Pallet - 3-Runner Base | 1200 x 1200 x 150 | 1000 KG | 2500 KG |

| 10# | Grid Pallet - 3-Runner Base | 1200 x 1000 x 150 | 1000 KG | 2500 KG |

| 24# | Grid Pallet - 3-Runner Base | 1100 x 1100 x 150 | 1000 KG | 2500 KG |

❓ Expert Insights: Plastic Pallet FAQ

Q1: What is the real-world difference between Dynamic and Static load?

Think of Dynamic Load as the "moving weight"—what the pallet can handle while on a forklift. Static Load is the "resting weight" on the floor. Always calculate your needs based on the Dynamic load if you plan on moving goods frequently; it's the safer metric for daily operations.

Q2: Is the steel tube reinforcement really necessary?

If you are floor-stacking light cartons, probably not. However, if you are using high-bay racking, steel tubes are a game-changer. They virtually eliminate the "creep" (permanent bending) that plastic can experience under heavy loads over time, significantly extending the life of your investment.

Q3: How do I know if I need HDPE or PP?

Generally, HDPE is the go-to for cold storage due to its excellent impact resistance at low temperatures. PP is often preferred for high-temperature environments or specific chemical handling. If you're unsure, our team can recommend the best polymer for your specific climate.