🏗️ Product Overview: Engineered for Industrial Strength

Our Single-Sided Fork Foot Plastic Pallets represent a significant step up in structural integrity. Unlike standard round-foot models, the "Fork Foot" (开叉脚) design features reinforced, wide-base supports that distribute weight more evenly across the pallet's surface.

These pallets are the workhorses of the manufacturing floor. Built from premium HDPE (High-Density Polyethylene), they are specifically designed to withstand the rigors of frequent forklift interaction and high-pressure stacking. If your operations involve heavy raw materials, automotive parts, or chemical drums, the Fork Foot series provides the stable foundation your inventory requires.

📊 Technical Specifications: Fork Foot Series

Reinforced design for superior static and dynamic load-bearing.

| Model | Dimensions (mm) | Dynamic Load (kg) | Static Load (kg) | Entry Type |

|---|---|---|---|---|

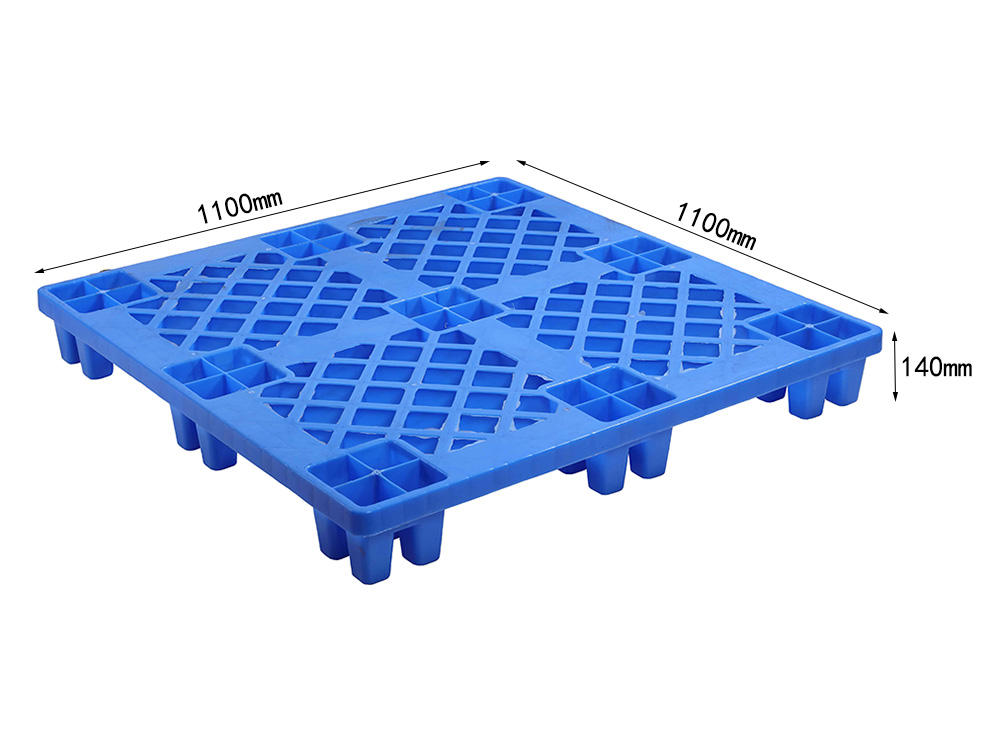

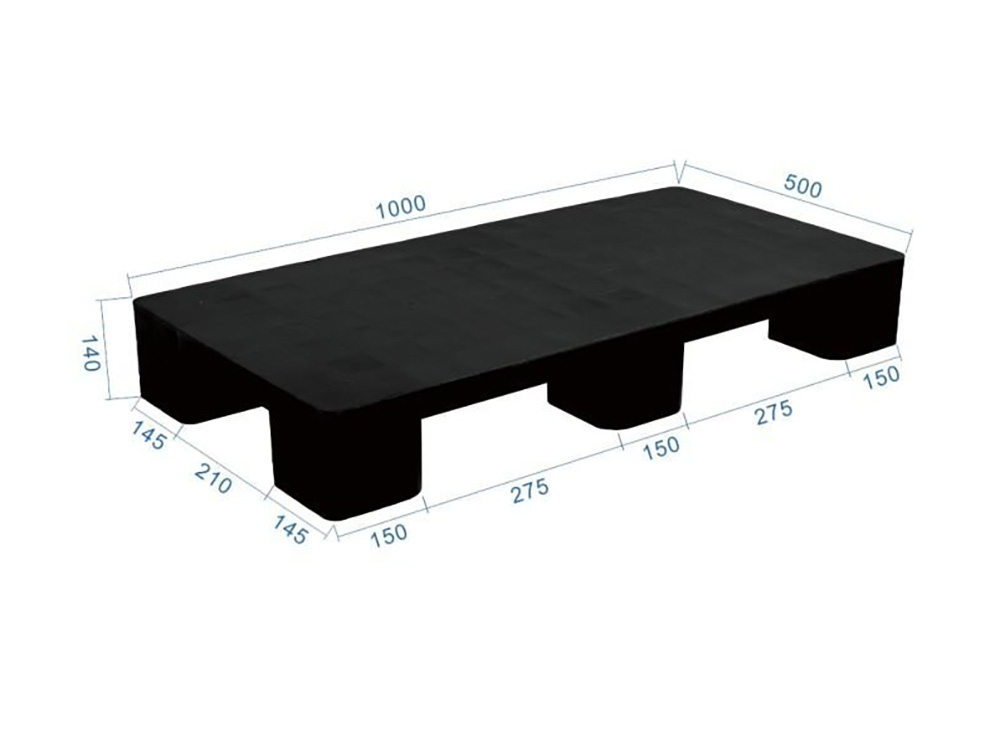

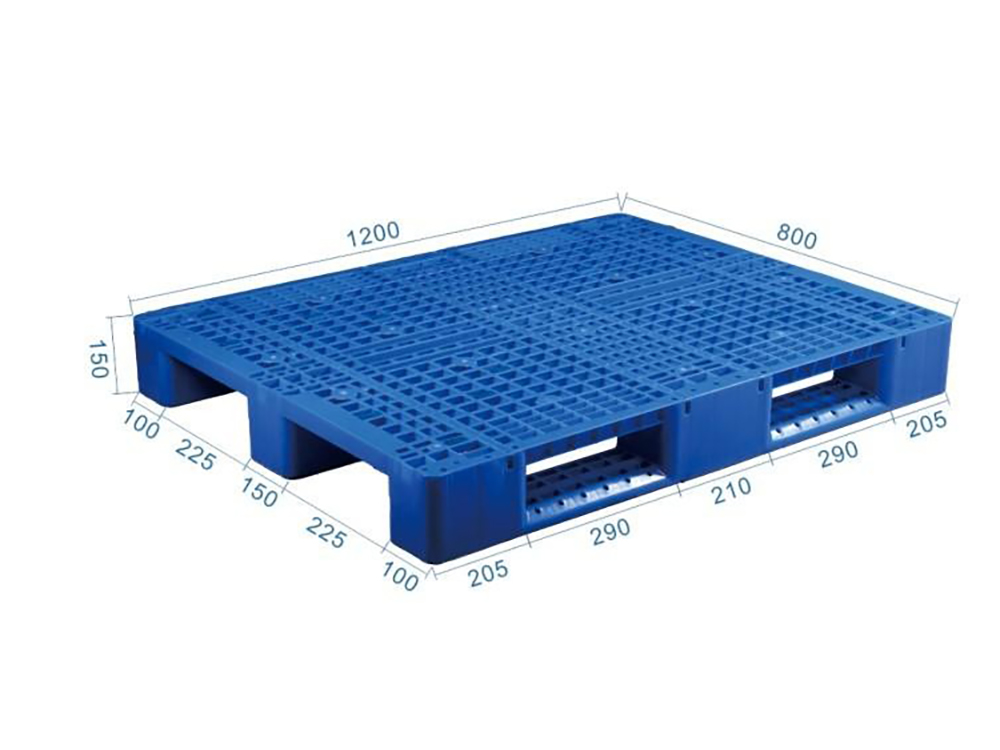

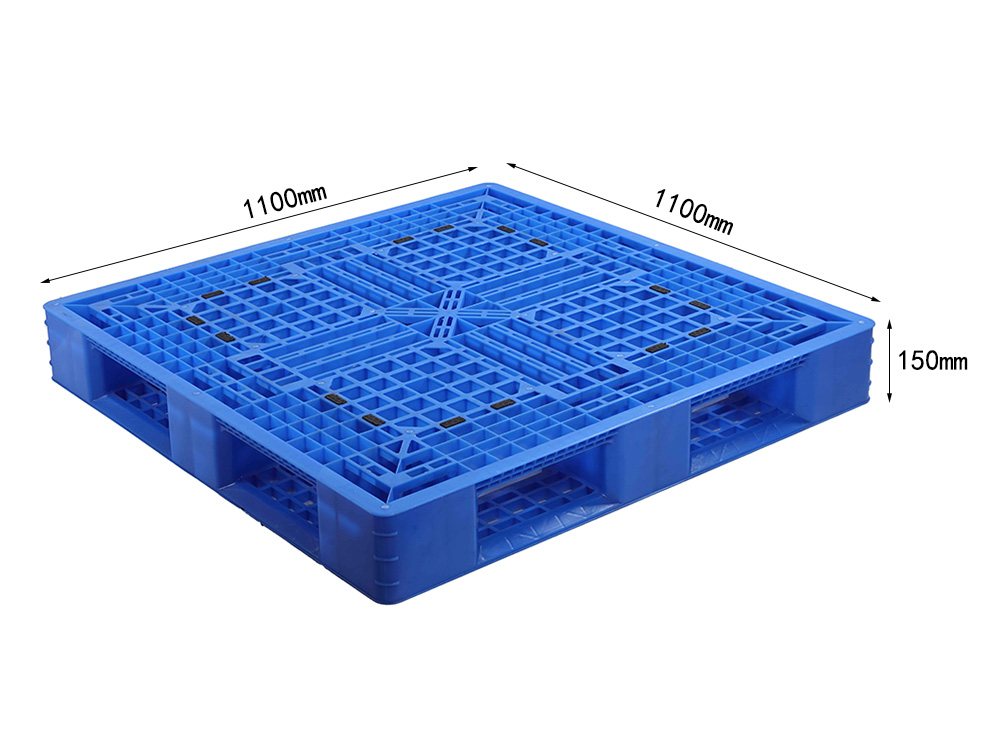

| A2# | 1100 × 1100 × 140 | 600 | 1000 | 4-Way Entry |

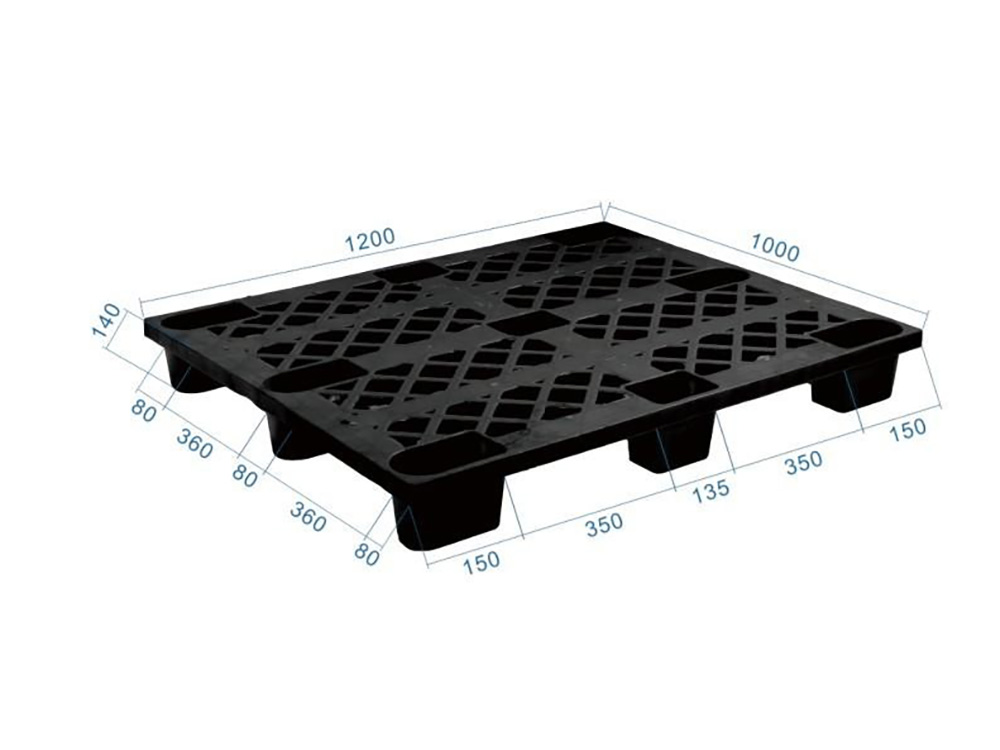

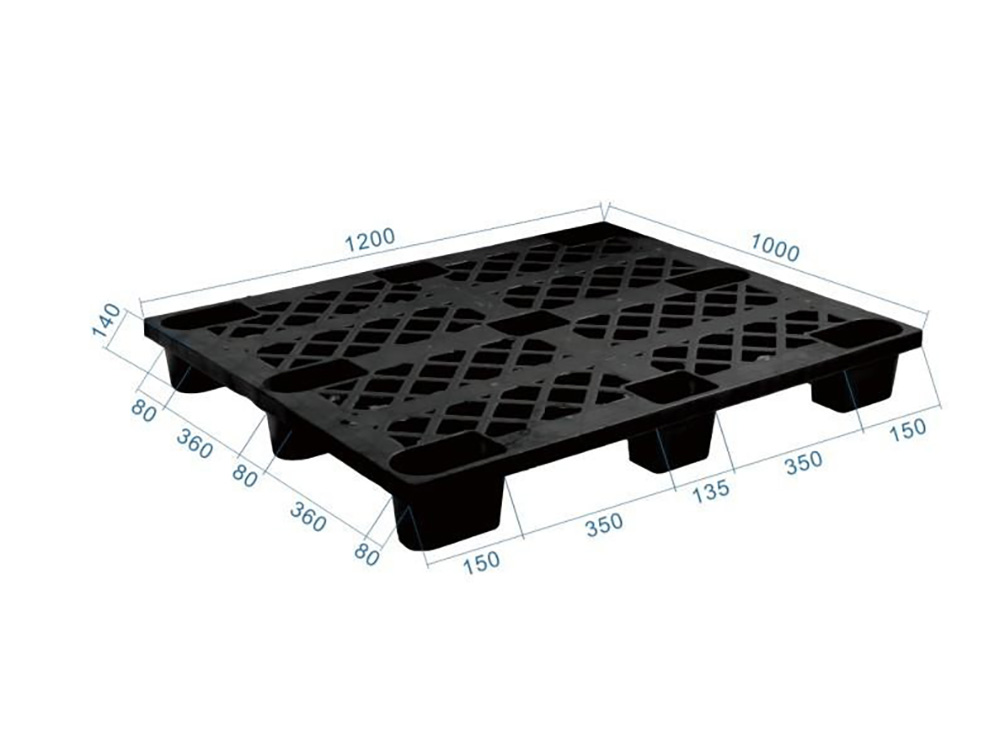

| A3# | 1200 × 1000 × 140 | 600 | 1000 | 4-Way Entry |

| 47# | 1200 × 1200 × 150 | 600 | 2500 | High-Static Load |

✨ Key Features & Advantages

- Reinforced Fork Entry: The wide-leg design protects the pallet from "fork-tip" damage, extending the product's lifespan in fast-paced environments.

- Superior Impact Resistance: Manufactured using high-pressure injection molding, these pallets absorb shocks better than wood or light-duty plastics.

- Anti-Slip Surface: Features a textured grid pattern to prevent cargo shifting during transport, ensuring worker safety and reducing product damage.

- Chemical & Moisture Proof: Resistant to oils, acids, and alkalis. They do not absorb moisture, ensuring the pallet weight remains constant regardless of the environment.

- Sustainable Durability: Designed for a 5–10 year service life and fully recyclable at the end of its cycle.

🏭 Ideal Application Scenarios

- Heavy Manufacturing: Perfect for moving metal components, machinery parts, and industrial equipment.

- Chemical & Petrochemical: The stable base is ideal for transporting 55-gallon drums and chemical containers.

- Automotive Logistics: Standardized sizes (like the 1200x1000 A3#) fit perfectly into automotive supply chain workflows.

- Construction Materials: Durable enough to handle the weight of tiles, bricks, and bagged cement in warehouse settings.

❓ Frequently Asked Questions (FAQ)

Q1: What makes the "Fork Foot" design better than "Round Foot" pallets?

A: While round foot pallets are great for light-duty export, the Fork Foot design offers a larger footprint on the ground. This provides better stability for heavier loads and prevents the pallet from "tilting" when being picked up by a forklift or pallet jack.

Q2: Can these pallets be used in high-traffic warehouses?

A: Yes. The Fork Foot series is specifically built for high-frequency use. The reinforced entry points are designed to withstand the daily wear and tear of forklift tines better than economy-grade pallets.

Q3: Is the 47# model suitable for stacking heavy goods?

A: Absolutely. With a Static Load capacity of 2500��, the 47# model is our top recommendation for heavy-duty stacking where floor space is limited and vertical storage is required.